•

Pitting (small pits or craters in metal surfaces) is caused by corrosion and can

lead to surface wear and eventually failure.

•

Brinelling is a type of surface. Brinelling is often caused by improper installation

of the U-joints. Do not confuse the polishing of a surface (false-brinelling), where

no structural damage occurs, with actual brinelling. False-brinelling is a

manufacturing characteristic that surface-polishes bearing races without actually

creating any damage. Technicians should learn to recognize false-brinelling to

avoid replacing bearings that are functionally sound.

4.6.0 Yoke Inspection

After removing the U-joint cross and bearing cups, inspect the yoke bores for damage

or burns. Some bore irregularities can be removed with a rat tail or half-round file,

followed by finishing with emery cloth.

Check the yoke bores for wear, using a go-no-go wear gauge. Use an alignment bar (a

bar with approximately the same diameter as the yoke bore) to inspect for misalignment

of the yoke lugs. Slide the bar through both yoke bores simultaneously. If the alignment

bar will not pass through both yoke bores simultaneously, the yoke has been distorted

either by disassembly malpractice or excessive torque and should be replaced. Next,

clean and inspect the mating yoke with an alignment bar gauge. Do not risk reusing a

defective yoke.

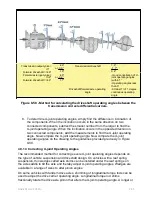

4.7.1 U-Joint Reassembly

Use the following procedure to assemble a driveshaft installing new U-joints.

1. Place the slip yoke end of the driveshaft assembly in a bench vise so that you

can see the phase mark made on disassembly. Locate the phase mark on the

main section of the driveshaft and assemble mating the slip joint. Double check

the phasing. An out-of-phase driveshaft will cause an immediate driveline

vibration.

2. Remove the new U-joint from its packing and separate the bearing caps from the

cross trunnions. Visually inspect the cross, ensuring that the one-way check

valve in each trunnion lube hole is present. Then position the cross into the

driveshaft yoke aligning the lube zerk fitting as close as possible to the slip spline

lube fitting. The zerk fitting should be directed toward the inboard side.

3. Paste some antiseize compound to the outside diameter of four bearing

assemblies. This facilitates installation and removal next time around. Angle the

cross and insert into the yoke. Fit the first bearing cup by inserting a trunnion into

the needle bearings, and then push the bearing cup into the yoke bore. When the

trunnion is inserted into the first bearing cup assembly, it is aligned. Insert the

opposing bearing cup into the yoke bore and press home. You can now insert the

lock tabs and fasteners, but do not torque yet.

CAUTION

If the bearing cap binds in the yoke bore, gently tap with a ball peen hammer in the

center of the bearing cap. Do not tap the outer edges of the bearing cap because this

could damage either the bearing cup or the yoke.

NAVEDTRA 14050A

8-60