shorter torque rod might be available from the manufacturer if shimming is not practical.

Some torque rods are adjustable.

As a rule, the addition or removal of a %-inch shim from the rear torque arm will alter the

axle angle approximately % degree. A % degree change in the pinion angle will typically

change a U-joint operating angle by about % degree.

Factors that can cause the U-joint operating angle to change are the following:

1. Suspension changes caused by worn bushings in the spring hangers, worn

bushings in the torque rods, or incorrect airbag height

2. Driveshaft adjustments

3. Stretching or shortening the chassis

4. Addition of an auxiliary transmission or transfer case into the driveline

5. Worn engine or transmission mounts

4.9.1.4 1.4 Checking Driveshaft Runout

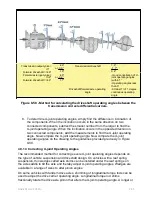

Any runout in a driveshaft can result in driveline vibrations. Driveshaft runout can be

checked by using a dial indicator.

Figure 8-59

shows the locations used to measure

driveshaft runout and the tolerance limits for total indicated runout (TIR). Note that these

are fine measurements, so before measuring, clean the surfaces from where you are

going to take the dial indicator readings.

Figure 8-59 - Checking

driveshaft runout.

4.9.2 and Alignment

Not only must the driveshaft be straight but the yokes attached to the transmission,

auxiliary transmission, and drive axles must also be true and straight and in alignment

with the shafts to which they are attached.

NAVEDTRA 14050A

8-67