3. Separate the case halves. Us a brass, plastic, or leather mallet to loosen the

parts.

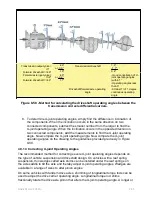

4. Remove he differential spider (cross), four pinion gears, two side gears, and six

thrust washers from inside the case halves (

Figure 8-72

).

5. If the pinion and crown gearset is to

be replaced, remove the hardware

that holds the gear to the flange case

half as follows:

•

Carefully center punch each rivet

head in the center on the crown

gear side of the assembly.

•

Drill each rivet head on the ring

gear side of the assembly to a

depth equal to the thickness of one

rivet head. Use a drill bit that is

1/32-inch smaller than the body

diameter of the rivets (

Figure 8-

73

).

•

Drive the rivets through the holes

in the ring gear and flange case

half. Press from the drilled rivet

head.

CAUTION

Figure 8-73 - Removing rivets

on a ring gear.

Do not remove the rivet heads or rivets

with a chisel and hammer because this

can damage the flange case half or

enlarge the rivet holes, resulting in loose

rivets.

6. Separate the case half and ring gear

using a press. Support the assembly

under the ring gear with metal or

wooden blocks and press the case

half through the gear (

Figure 8-74

).

7. If the differential bearings need to be

replaced, remove the bearing cones

from the case halves. Use a bearing

puller or press to remove them.

Removing Drive Pinion and Bearing Cage

1.

Fasten a yoke bar or flange bar to the

input yoke to prevent it from turning

while you remove the nut (

Figure 8-

75

).

Figure 8-74 -

Pressing the

flange case half out of the

crown. gear.

2.

Remove the retaining nut from the drive pinion. Then remove the yoke or flange

bar.

NAVEDTRA 14050A

8-76