Figure 8-75 -

Removing the A input flange or B yoke.

3.

Remove the yoke or flange from the drive

pinion. If the yoke or flange is tight on the

pinion, use a puller to remove it.

4.

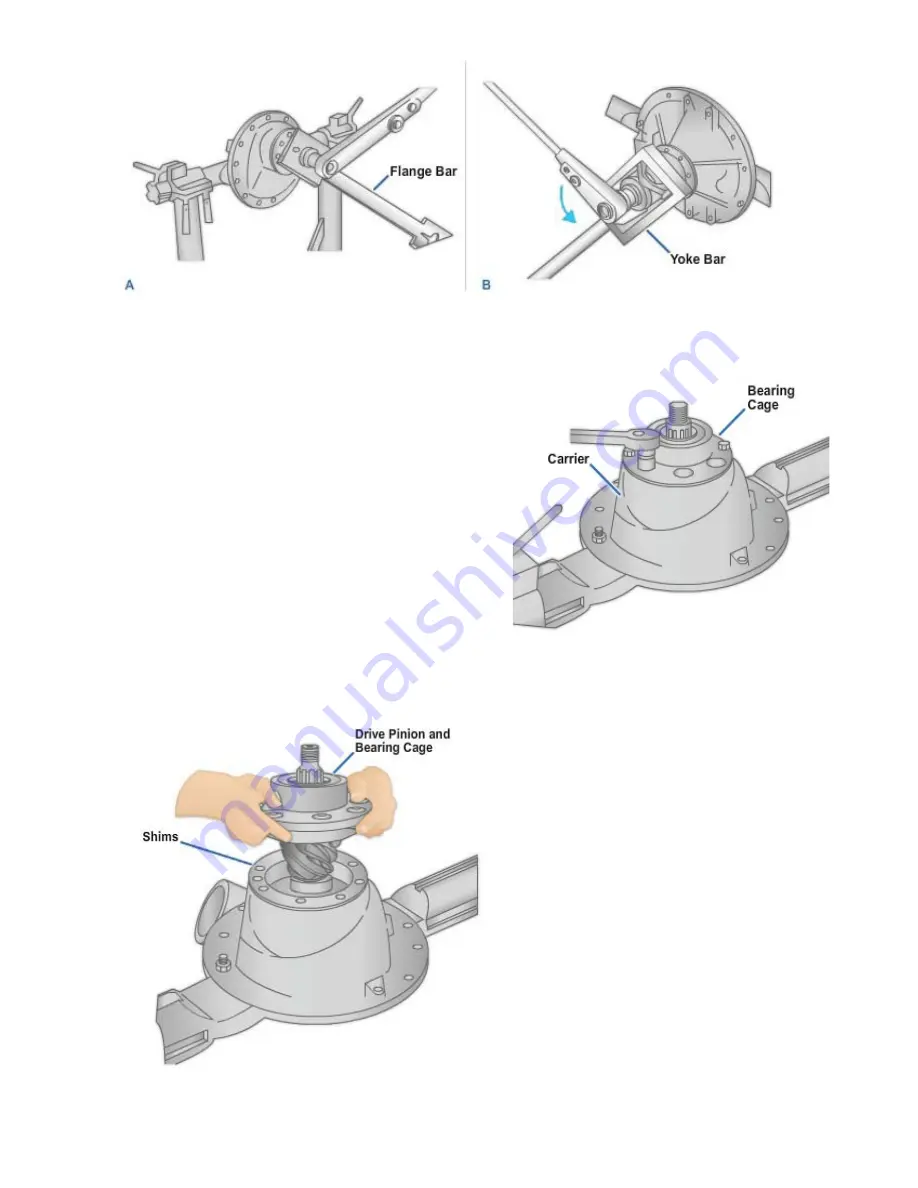

Remove the fasteners that retain the

bearing cage in the center in the carrier

(

Figure 8-76

).

5.

Remove the cover and seal assembly and

the gasket from the bearing cage. If the

cover is tight on the bearing cage, use a

brass drift and hammer for removal.

6.

If the pinion seal is damaged, remove the

seal driver. If a press is not available, use

a screwdriver or small pry bar for removal.

Discard the pinion seal.

Figure 8-77 - Removing the drive pinion

and bearing cage.

Figure 8-76 -

Bearing cap

removal.

7.

Remove the drive pinion

and bearing cage, plus the

shims from the carrier

(

Figure 8-77

).

8.

If the shims are in good

condition, keep them and

use them for reassembly

of the carrier.

9.

If the shims are to be

discarded because of

damage, measure the

shim pack total thickness

with a micrometer. Record

the dimension. You will

need it to calculate the

depth of the drive pinion in

the carrier when the

gearset is installed.

NAVEDTRA 14050A

8-77