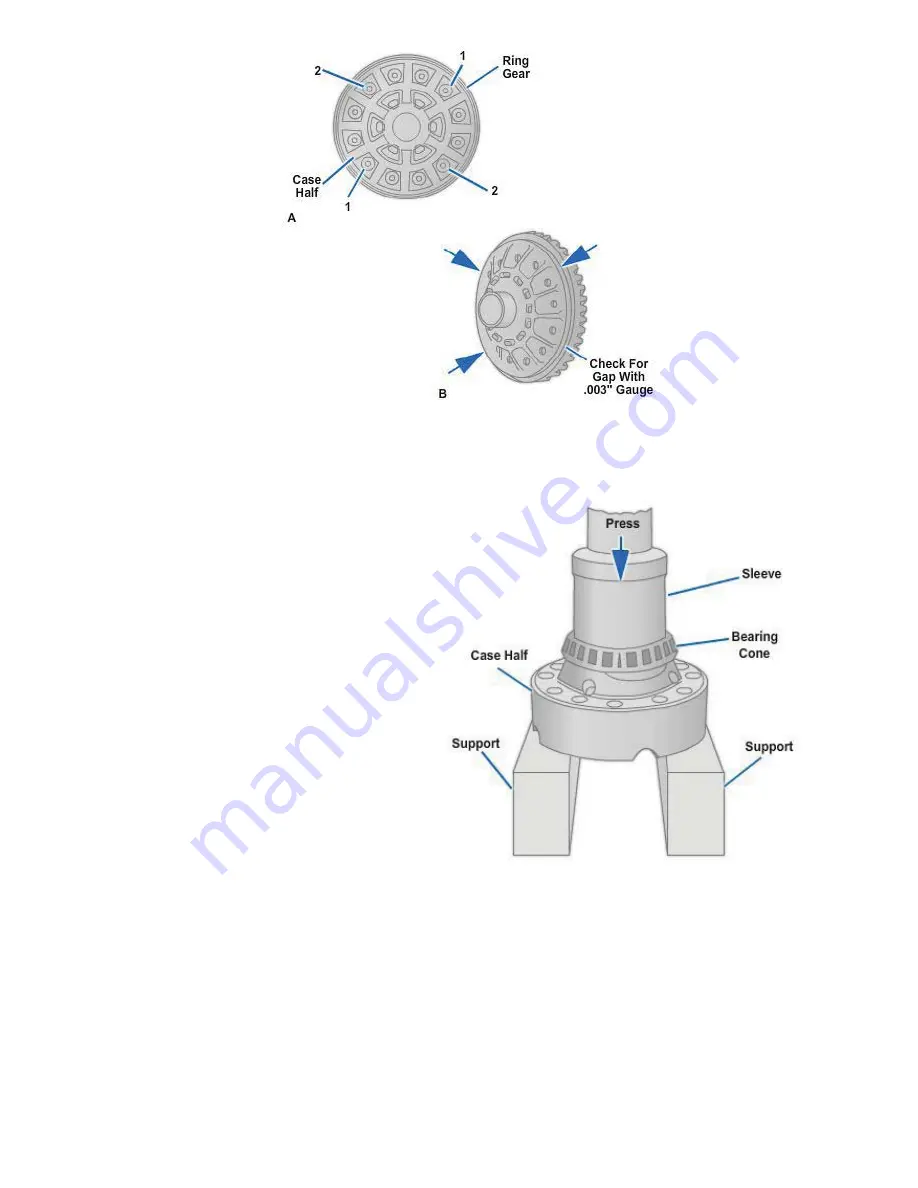

Figure 8-84 - Installing rivets to crown gear.

6.

Install the bearing cones on

both halves (

Figure 8-85

).

Use a press and sleeve if

necessary to install the

cones.

7.

Apply axle lubricant on the

inside surfaces of both case

halves, spider, thrust

washers, side gears, and

differential pinions.

8.

Place the flange case half

on the bench with the crown

gear teeth facing upward.

9.

Install one thrust washer

and side gear into the flange

case half (

Figure 8-86)

.

10.

Install the spider, differential

pinions, and thrust washers

into the flange case half

(

Figure 8-87

).

11.

Install the second side gear

Figure 8-85 - Bearing cone installation in

case half.

and thrust washer over the spider and differential pinions.

12.

Put the plain half of the differential case over the flange half and gears. Rotate

the plain half as needed to align the match marks.

13.

Install hardware into the case halves. The distance between fasteners must be

equal. Tighten the fasteners to the correct torque value in a pattern opposite

each other.

14.

Check the differential rolling resistance of the differential gears.

NAVEDTRA 14050A

8-82