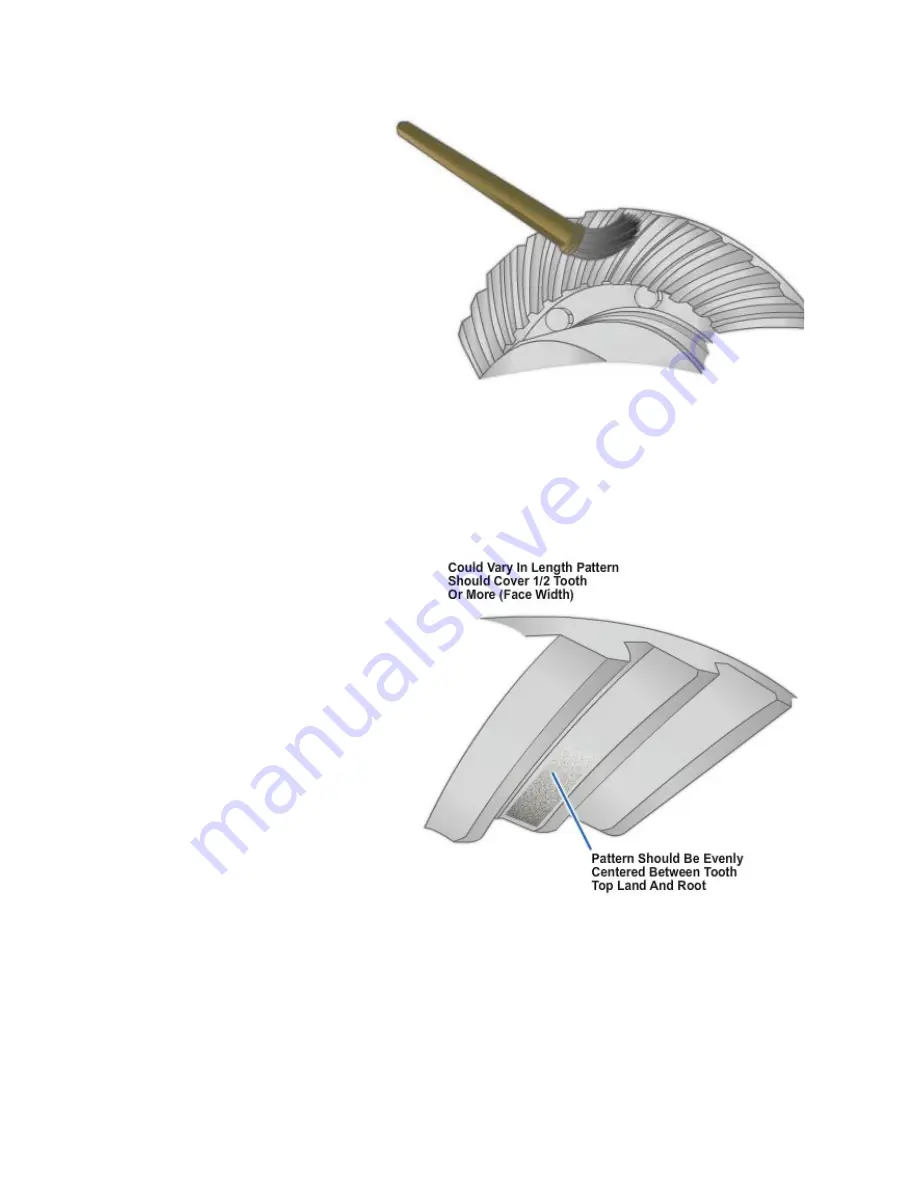

Checking tooth contact pattern

on a new gearset.

Paint or coat

12 crown gear teeth with a

marking compound such as

white grease and roll the gear to

obtain a tooth contact pattern

(

Figure 8-97)

. Machine blue, also

called Prussian blue, can be

used. Machine blue is a deep

blue dye mixed in a grease-like

substance. Use a small stiff

bristle brush to apply a light even

coat. A correct pattern should be

well centered on the crown gear

teeth with lengthwise contact

clear of the toe (

Figure 8-98

).

The length of the pattern in an

unloaded condition will be

approximately one-third to two-

thirds of the crown gear tooth in

most models and ratios.

Checking tooth contact pattern

on a used gearset.

Used

gearing will not usually display

the square, even contact pattern

found in new gearsets. The gear

will normally have a pocket at the

toe-end of the gear tooth that

tails into a contact line along the

root of the tooth (

Figure 8-99

).

The more use a gear has had,

the more the line becomes the

dominant characteristic of the

pattern.

Figure 8-97 - Application of a compound

to check tooth contact.

Figure 8-98 - Correct tooth contact pattern

for new gearing.

NAVEDTRA 14050A

8-90