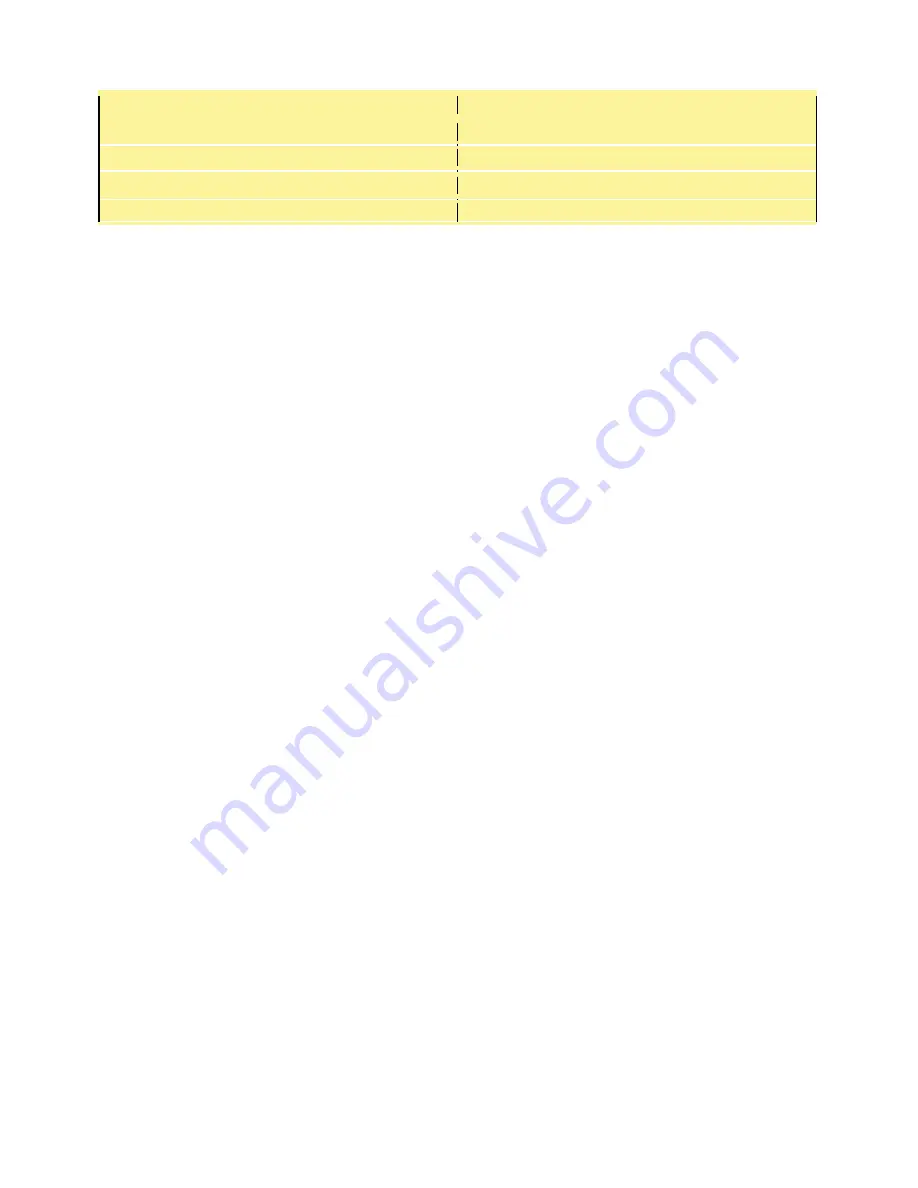

Ambient Temperature Range

Correct Grade

-40°F to -15°F

75W

-15°F to 100°F

80W-90

-15°F and above

80W-140

10°F and above

85W-140

Figure 8-107 - Proper grade of lubricant.

Most OEMs approve the use of synthetic lubricants as long as they meet API-GL-5

classification standards. Due to the wide variety of operating extremes that vehicles and

off-road equipment are subjected to, it is difficult to determine ideal drain intervals for all

vehicles and equipment. Vehicles invariably use mileage, whereas off-road equipment

service intervals are usually measure in hours of operation.

5.2.3 Contaminated Lubricant

It is not recommended to mix different brands of lubricants. Not all lubricants are

compatible with each other. Every effort should be made to prevent the mixing of

different lubricants in axle assemblies. Some additives used by certain manufactures

are not compatible with other manufacturer's additives. Never mix different brands of

gear lube. Some synthetic oils, when mixed with petroleum-based oil, will thicken. This

can lead to foaming, which can result in early component failure. Water, dirt, and wear

particles can cause extensive damage in a short period of time. Water can enter the

axle assembly through a faulty shaft seal or through the carrier to a banjo housing joint.

Wear particles are generally a result of normal wear and can be minimized by the use of

magnetic drain plugs. The magnets collect metal particles that settle to the bottom of the

axle housing during shutdown periods. Some manufacturers use an oil pump in the

drive axle to distribute oil and a filter in the circuit to filter out dirt particles.

5.2.4 ts of Lubrication Failures

Whenever a lubricant does not perform up to the vehicle or equipment application

standards, the life of the internal components will be shortened. Following is a list of

causes and effects that may occur as a result of lubrication failures:

1. Lubrication that is contaminated with water can cause scoring, etching, or pitting

on the running surfaces of the gears and bearings.

2. Underfilling the axle assembly may lead to metal-to-metal contact, which can

lead to high friction that can cause overheating and result in oil breakdown. This

will usually melt metal surfaces. The internal parts will often be blackened from

the heat.

3. The use of an improper lubricant, which includes the practice of mixing different

oils, may lead to surface etching or lubricant breakdown, leading to metal-to

metal contact.

4. Using a viscosity that is not suitable for the application temperatures may result

in a lubrication film breakdown, leading to severe scoring and galling. The

internal gears will often be blackened from the heat.

NAVEDTRA 14050A

8-97