the oil its increased load-carrying capacity. This reason alone makes more frequent oil

change intervals desirable.

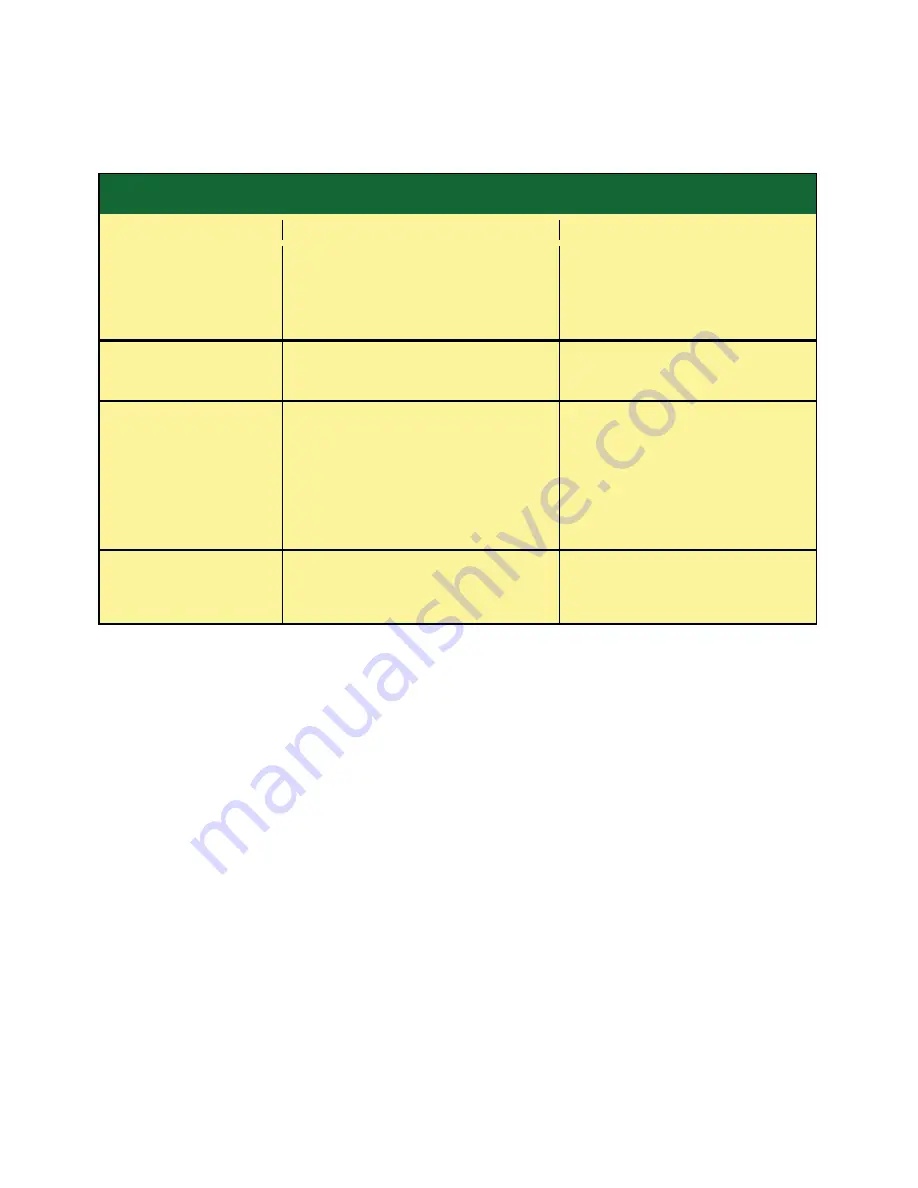

Refer to

Figure 8-109

for drive axle quick reference for troubleshooting the drive axle.

Drive Axle Troubleshooting

Symptom

Probable Cause

Remedy

Noisy on turns only

Differential pinion gears tight on spider

Side gears tight in differential case

Differential or side gears defective

Excessive backlash between side

gears and pinion

Overhaul drive axle and make

necessary adjustments.

Intermittent noise

Crown gear not running true

Loose or broken differential bearings

Overhaul axle and replace defective

crown gear or differential bearings.

Constant noise

Lubricant incorrect

Lube level low

Crown gear teeth chipped or worn;

loose or worn bearings

Crown gear and pinion not in

adjustment for correct tooth contact

Too much or too little pinion-to-gear

backlash or overlap of wear pattern

Verify type and class of lubricant

used.

Check lube level and fill if needed.

Overhaul axle and replace defective

crown gear, pinion, or bearings.

Adjust crown gear and pinion for

correct tooth contact.

Adjust gear backlash.

Rear wheels do not drive

(driveline rotating)

Broken axle shaft

Crown gear teeth stripped

Differential pinion or side gear broken

Differential spider broken

Replace broken axle.

Overhaul axle and replace defective

crown gear, pinion, or spider.

Figure 8-109 Drive axle quick reference troubleshooting guide.

Summary

This chapter presented extensive information on troubleshooting the drivechain

assemblies of the transmission, transfer case, power takeoff, propeller shafts, and

differentials.

Of the vast number of vehicles and construction equipment within the Seabee table of

allowance, it is safe to say that almost every piece of CESE includes one of these

assemblies. These assemblies give the vehicle or equipment its particular

characteristic.

Even in the electronic age, working on these particular assemblies still requires the

mechanic to possess the skills of disassembly and reassembly of components,

inspecting components for wear and damage, and general hands-on mechanical know-

how.

Lastly, and most importantly, you still will always be required to refer to the service

manual for each vehicle or piece of equipment you are working on for the detailed

specifications that will enable you to do the job correctly in order to turn out a finished

product that operators can operate safely.

NAVEDTRA 14050A

8-99