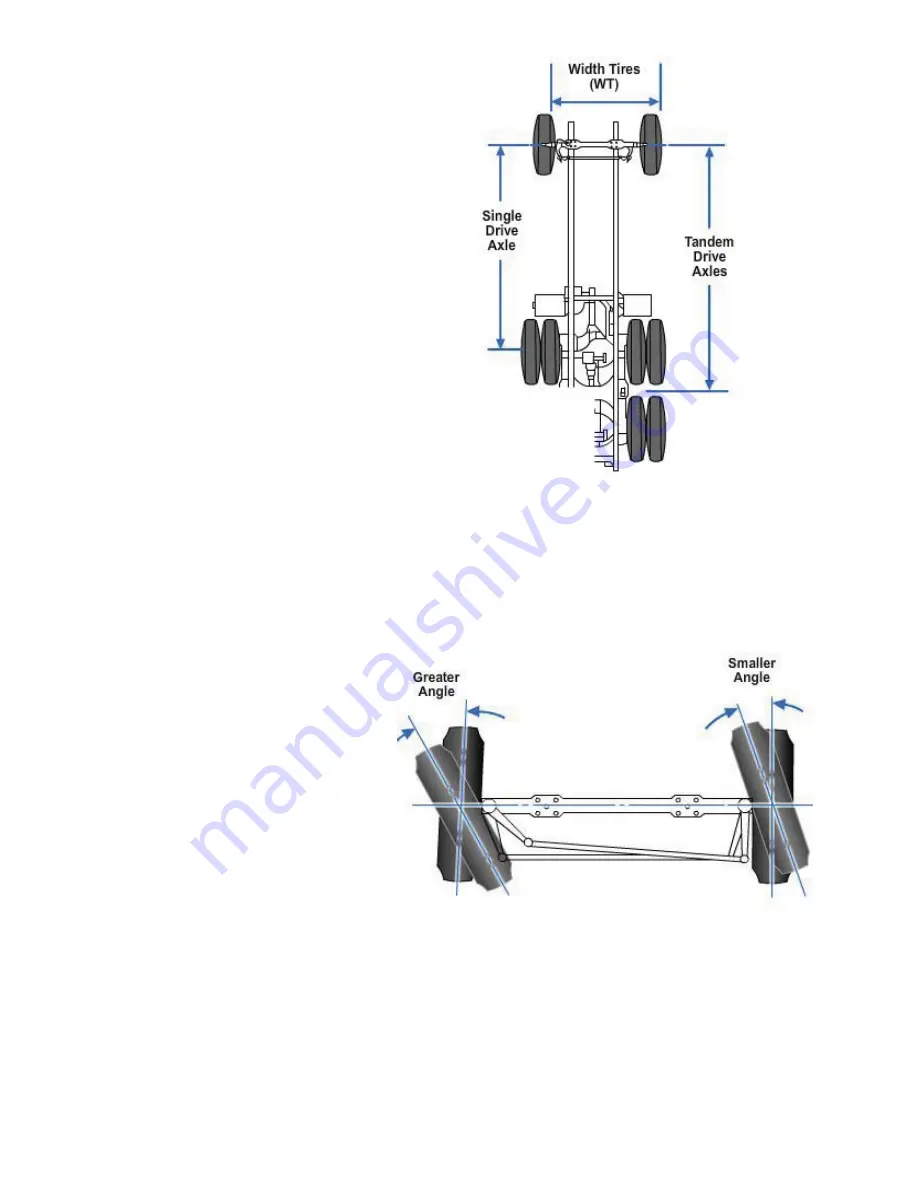

Toe-out on turns is accomplished

by having the ends of lower

steering arms (those that connect

to the tie-rods) closer together

than the kingpins, as shown in

Figure 9-11. Actual toe-out during

a turn depends on the length and

angle of the steering control arms

and length of the cross tube.

Even if the toe-in setting with the

wheels in a straight-ahead

position is correctly adjusted, a

bent steering arm can cause the

toe-out to be incorrect, causing

tire scuffing.

Turning radius angle should be

checked using radius plates. To

check the turning radius angles,

you can use the following:

1. Position the front wheels

on the radius plates and in

the straight-ahead

position.

2. Remove the locking pins

from each plate and adjust

the scale on the edge of

the plates so that the

pointers indicate zero.

3. Turn the wheels to the

right until the indicator

gauge at the left wheel

reads 20 degrees. Then

read and record the angle

of the right wheel.

4. The right wheel should

then be turned to an angle

of 20 degrees. The left

wheel should read the

same turn as the right

wheel did in the previous

step. If the angle is

different, check the

steering arms for damage

and replace any that are

bent. Do not attempt to

straighten them.

Figure 9-10 - Measuring wheel base for

single and tandem drive axles.

Figure 9-11 -

In a toe-out condition on

turns, the inside wheel turns at a greater

distance than the outside wheel.

NAVEDTRA 14050A

9-11