•

Chain hoists must be properly attached to the parts being lifted. Always use

proper attaching devices of sufficient strength rating to attach the hoist to the

object being lifted.

•

Mechanical locks or stands must be engaged after lifting a vehicle or equipment

on any kind of hoist.

•

Do not use any lift, hoist, or jack that you believe to be defective or not operating

properly. Tag it immediately and immediately take it out of service. Report it to

the shop supervisor so it can either be repaired or disposed of.

•

Make sure all persons and obstructions are clear before raising or lowering any

heavy components or the vehicle.

•

Avoid working, walking, or standing under suspended objects that are not

mechanically supported.

2.1.4 Tension

To hold a 2,500- to 5,000- pound vehicle above the ground, the suspension must be

very powerful. The weight of the vehicle puts the spring under a great deal of tension.

This tension, known as spring tension, can injure you if it is not properly released. If you

remove the bolts that secure parts under spring tension without properly releasing the

spring tension, the parts could fly apart with great force. This force is great enough to

break ribs or crush hands and feet. Always determine whether a part is under spring

tension before removing its fasteners. If necessary, compress the spring to release the

tension. If the fasteners seem to be under tension as the first few threads are loosened,

stop immediately and determine why the part is still under spring tension. Never assume

that the parts are not under tension.

2.2.1 Tools for Frontend Alignment

Alignment machines.

Using an alignment machine is the most convenient and reliable

way to align a vehicle. The alignment machine takes the place of all the individual

alignment units. It has alignment units, usually called heads, that attach to the wheels of

the vehicle. The heads are used in combination with a special rack, front and rear

turning plates, and other components to check all alignment angles in one operation.

You may have once used an older alignment machine that used light beams to display

readings on a screen mounted in front of the vehicle. Heads installed on the front

wheels generated the light beams, which were directed on the screen. Markings on the

screen allowed the mechanic to translate the position of the light beams into alignment

angles.

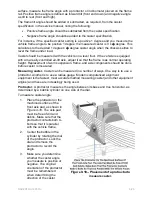

Electronic align machines are now commonly used. These machines have four heads,

one for each wheel. When all four heads are installed on the wheels, they transmit a

laser beam or infrared light to each other. The system's computer receives readings

from each of the heads and computes the front and rear wheel alignment. The

alignment readings are displayed on a computer screen.

Alignment machines use flat panels that contain target dots. The panels attach to the

vehicle's wheels. The alignment machine's computer calculates the position of the

target dots and displays the vehicle alignment on the computer screen. This system is

simpler to set up than older systems.

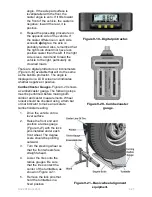

Alignment wrenches.

Various specially designed wrenches are needed to perform

alignments. Alignment wrenches are specially shaped wrenches. These wrenches are

NAVEDTRA 14050A

9-16