and slant of the light lines on the display boards. If necessary, record the camber and

toe readings.

Checking Caster.

To check caster, be sure the brake pedal compressor is applied.

Most alignment equipment manufacturers specify that the heads be locked into position

(unable to pivot on the mounting frame) for the caster check. Turn the wheels to the left

and right, according to the alignment machine manufacturer's instructions. This can be

done by turning the wheels themselves or by turning the steering wheel. When using

the steering wheel to turn the wheel, do not sit in or lean on the vehicle. This will change

suspension height and affect the readings. On some systems, you must turn the

steering wheel until the screen indicates that the readings have been obtained. On other

systems, the turntables must be turned an exact amount, usually 20°. Record the caster

reading if the alignment machine does not automatically do this.

Checking Steering Axis Inclination.

Steering axis inclination (SAI) is usually checked

as part of the caster checking process. SAI should be checked whenever there is

evidence of collision damage or the vehicle has a handling or tire wear problem that

cannot be accounted for by another cause. The brakes should be locked for the SAI

check. Some equipment manufacturers specify that the heads be free to pivot on the

head frame when both caster and SAI are checked in one position.

Checking Toe on Turns.

Toe-out on turns is seldom incorrect, but it should be checked

whenever you suspect steering arm damage or when the tires squeal excessively on

turns. To check toe-out on turns, the brake pedal depressor should be in place. To

make this check, turn one of the front wheels inward until the turntable indicator reads

20°. After this is done, move to the other side of the vehicle and read the indicator on

that turntable. The reading should be slightly more than 20°. Record this reading; then

turn the wheel inward to the 20° indicator on the turntable. Read the indicator on the

other turntable. This reading should also be slightly more than 20°. Compare the

readings with specifications. If the readings are incorrect, the steering arms should be

replaced.

Adjusting Toe with Trammel Bars.

When a vehicle needs only toe adjustment, a

trammel bar can be used. To use a trammel bar, rise both wheels off the ground and

scribe a mark completely around the tire. Hold a punch or other pointed tool against the

outside of each tire tread as another mechanic spins the tire. Then place the vehicle on

the ground and drive it back and forth a few times to settle the suspension. Use the

trammel bar to measure the distance between the scribed lines at the front of the tire.

Then measure the distance between the lines at the rear of the tires. The measurement

can also be done with a steel tape if you have an assistant to hold one end of the tape.

No matter what type of measurement device is used, the measuring point should be at

the same height at the front and rear of the tire. The difference in the front and rear

distances is the toe. If the measurement is greater at the rear, the vehicle is toed. If the

measurement is greater at the front, the vehicle is toed out. The trammel bar method

will give an acceptable toe measurement, but it cannot be used to center the steering

wheel.

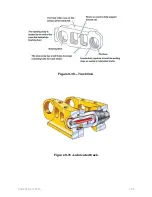

3.4.0 Caster and Camber-Trucks with Solid Axles

Many trucks use a solid or twin I-beam front axle, and there are no provisions for

adjusting caster and camber. The only way to adjust caster and camber on these trucks

is to replace the upper ball joint bushing with a special eccentric bushing, or sleeve.

NAVEDTRA 14050A

9-24