angle. If the axle pad surface is

level/parallel with the floor, the

caster angle is zero. If it tilts toward

the front of the vehicle, the caster is

negative; toward the rear, it is

positive.

4.

Repeat the preceding procedure on

the opposite side of the vehicle. If

the caster difference on each side

exceeds

�

degree, the axle is

probably twisted. Also, remember that

the right side should not have less

positive caster than the left. If the right

side is less, it will tend to lead the

vehicle to the right, particularly on

crowned roads.

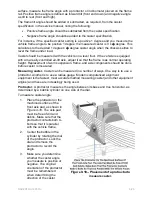

There are digital protractors or inclinometers

(

Figure 9-19

) available that will do the same

as the bubble protractor. The angle is

displayed on a LCD screen and indicates

whether negative or positive.

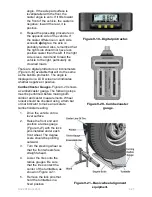

Camber/Caster Gauges. Figure 9-20

shows

a camber/caster gauge. The following steps

must be performed before making both

camber and caster measurements. Wheel

runout should be checked using a tram bar

or dial indicator to make an accurate

camber/caster reading.

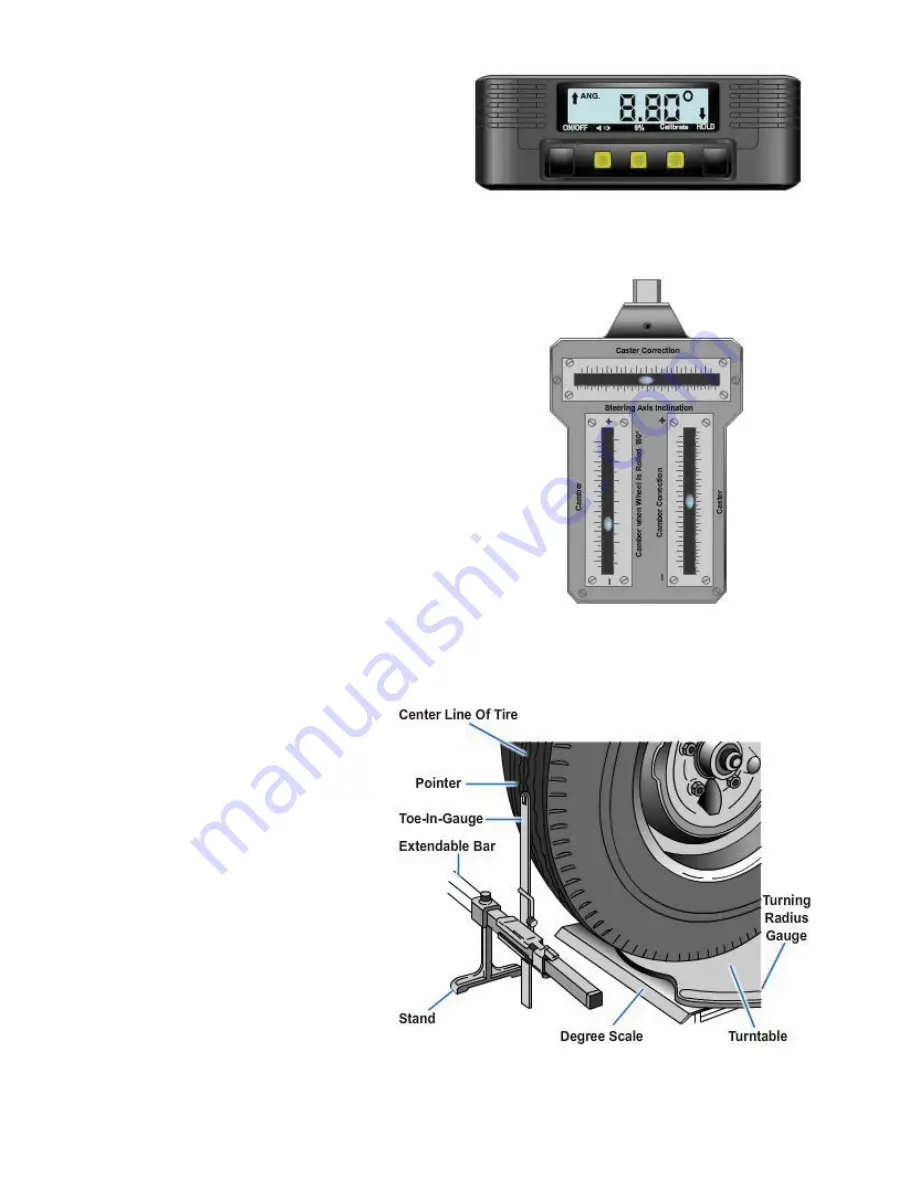

1.

Drive the vehicle onto a

level surface.

2.

Raise the front end and

position a radius gauge

(

Figure 9-21

) with the lock

pins installed under each

front wheel. The degree

scale should be pointing

outward.

3.

Turn the steering wheel so

that the front wheels face

straight ahead.

4.

Lower the tires onto the

radius gauges. Be sure

that the tires contact the

center of the turntables, as

shown in

Figure 9-21

.

5.

Remove the lock pins that

hold the turntables in a

Figure 9-19 - Digital protractor.

Figure 9-20 - Camber/caster

gauge.

fixed position.

Figure 9-21 - Basic wheel alignment

equipment.

NAVEDTRA 14050A

9-27