1.0.0 CLUTCH SYSTEMS

It is important to briefly review the purpose of the clutch and also the various types of

clutches. The clutch permits the operator to couple and uncouple the engine and

transmission. When the clutch is in the

coupling

(or normal running) position, power

flows through it from the engine to the transmission. If the transmission is in gear, power

flows through to the vehicle wheels, so the vehicle moves. Essentially, the clutch

enables the operator to

uncouple

the engine temporarily, so the gears can be shifted

from one forward gear position to another or into reverse or neutral. The flow of power

must be interrupted before the gears are shifted; otherwise, gear shifting is extremely

difficult if not impossible.

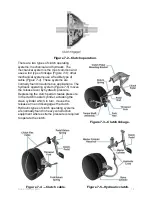

The clutch assembly (

Figure 7-1

) contains a friction disc, or driven plate, about a foot in

diameter. It also contains a spring arrangement and a pressure plate for pressing the

disc tightly against the face of the flywheel. The friction disc is splined to the clutch

shaft. The splines consist of two sets of teeth: an internal set on the hub of the friction

disc and a matching external set on the clutch shaft. They permit the friction disc to slide

back and forth along the shaft but force the disc and the shaft to rotate together.

Figure 7-1 -

Single disc clutch.

The flywheel, attached to the end of the engine crankshaft, rotates when the engine is

running. When the clutch is engaged in the coupling position, the friction disc is held

tightly against the flywheel by the pressure plate springs so that it rotates with the

flywheel. This rotary motion is carried through the friction disc and clutch shaft to the

transmission.

To disengage (or uncouple) the clutch, the clutch operator presses the clutch pedal

down. This causes the clutch fork to pivot so the clutch release bearing is forced inward.

As the release bearing is moved inward, it operates the pressure plate release levers

(

Figure 7-2

). The release levers take up the spring pressure and lift the pressure plate

away from the friction disc. The friction disc is no longer pressed against the flywheel

face, and the engine can run independently of the power train. Releasing the clutch

pedal permits the clutch fork to disengage the release bearing, so the springs will again

cause the pressure plate to force the friction disc against the flywheel face to rotate

together.

NAVEDTRA 14050A

7-3