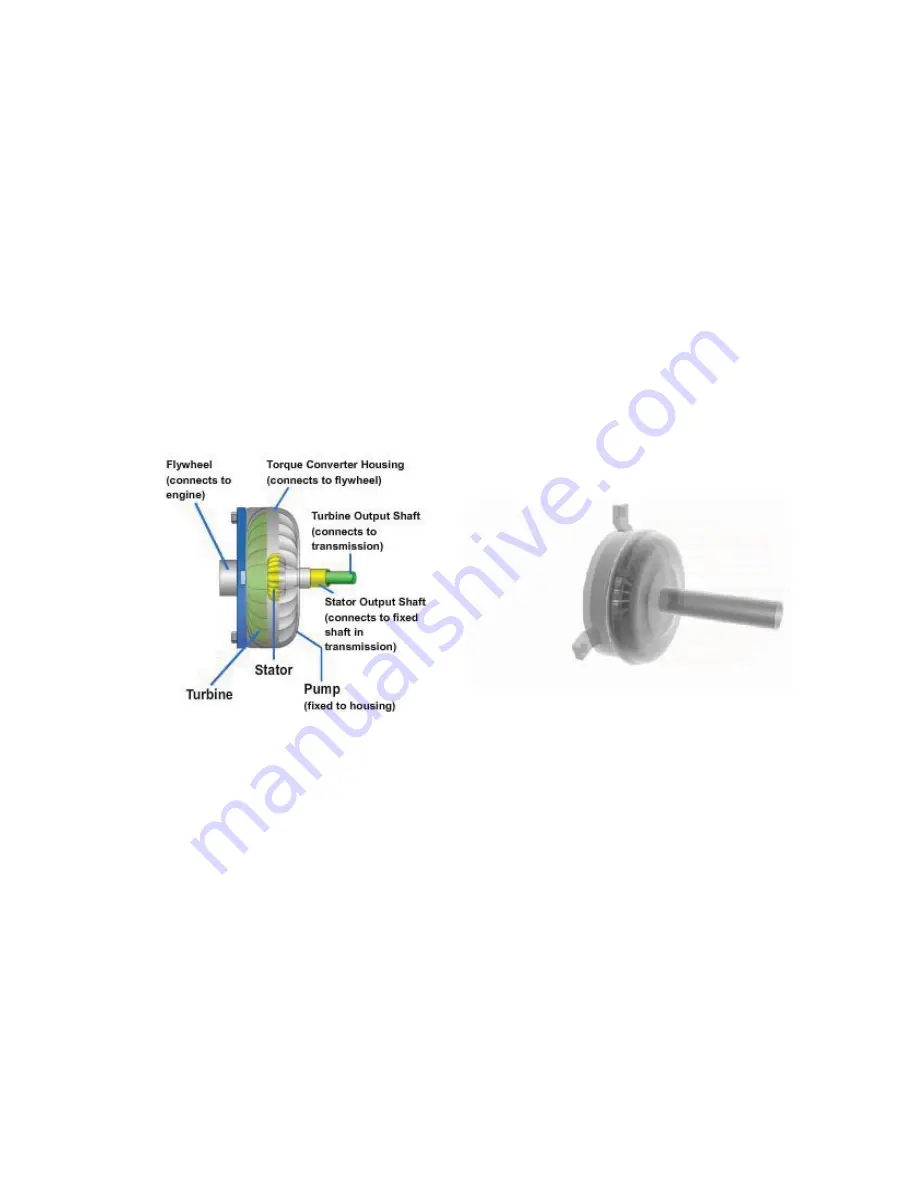

2.3.0 Coupling (Torque Converter Operation)

The automatic transmission is coupled to the engine through a torque converter. The

torque converter is used with the automatic transmission because it does not have to be

manually disengaged by the operator each time the vehicle is stopped. The cushioning

effect of the fluid coupling within the torque converter allows for shifting without

interruption of engine torque application.

The torque converter serves two primary functions. First, it acts as a fluid coupling to

connect engine power smoothly through oil to the transmission gear train. Second, it

multiplies the torque from the engine when additional performance is desired.

The torque converter, as shown in

Figure 7-10

, consists of the pump (driving member),

the turbine (driven or output member), and the stator (reaction member). The converter

cover is welded (some maybe bolted) to the pump to seal all three members in an oil-

filled housing. The converter cover is bolted to the engine flex-plate, which is bolted

directly to the engine crankshaft. The converter pump is, therefore, mechanically

connected to the engine and turns at engine speed whenever the engine is operating.

Figure 7-10 - Torque converter.

Figure 7-11 - Torque converter

operation.

When the engine is running and the converter pump is spinning (

Figure 7-11

), it acts as

a centrifugal pump, picking up oil at the center and discharging this oil at its rim between

the blades. The shape of the converter pump shells and blades causes this oil to leave

the pump, spinning in a clockwise direction toward the blades of the turbine. As the oil

strikes the turbine blades, it imparts a force to the turbine, causing it to turn. When the

engine is idling and the converter is not spinning fast, the force of the oil is not great

enough to turn the turbine with any efficiency. This allows the vehicle to stand in gear

with the engine idling. As the throttle is opened and the pump speed is increased, the

force of the oil increases and the engine power is more efficiently transmitted to the

turbine member and the gear train. After the oil has imparted its force to the turbine, the

oil follows the contour of the turbine shell and blades so that it leaves the center section

of the turbine spinning counterclockwise.

Because the turbine member has absorbed the force required to reverse the direction of

the clockwise spinning of oil, it now has greater force than is being delivered by the

NAVEDTRA 14050A

7-11