2.5.1 Preventive Maintenance

Normal preventive maintenance includes:

•

Checking the transmission fluid daily

•

Adjusting the shifting and kickdown linkages

•

Adjusting lockup bands

•

Changing the transmission fluid and filter at recommended service intervals

(Example: 15,000 miles or yearly for heavy or severe service)

2.5.1.1 Checking the Fluid

The operator is responsible for first echelon (operator's) maintenance. The operator

should be trained not only to know to look for the proper fluid level, but also to know

how to look for discoloration of the fluid and debris on the dipstick.

Fluid levels in automatic transmissions are most commonly checked at operating

temperature. This is important to know, since the level of the fluid may vary as much as

three quarters of an inch between hot and cold.

The fluid should be either reddish or clear. The color varies due to the type of fluid. (For

example, construction equipment using OE-10 will be clear). A burnt smell or brown

coloration of the fluid is a sign of overheated oil from extra heavy use or slipping bands

or clutch packs. The vehicle should be sent to the shop for further inspection.

CAUTION

Not all transmission fluids are the same. Before you add fluid, check the manufacturer's

recommendations first. The use of the wrong fluid will lead to early internal parts failure

and costly overhaul.

Overfilling the transmission can result in the fluid foaming and the fluid being driven out

through the vent tube. The air that is trapped in the fluid is drawn into the hydraulic

system by the pump and distributed to all parts of the transmission. This situation will

cause air to be in the transmission in place of fluid and in turn cause slow application

and burning of clutch plates and facings. Slippage occurs, heat results, and failure of

the transmission follows.

Another possible, but remote, problem is water, indicated by the fluid having a "milky"

appearance. A damaged fluid cooling tube in the radiator (automotive) or a damaged oil

cooler (construction) could be the problem. The remedy is simple. Pressure-test the

suspected components and perform any required repairs. After repairs have been

performed, flush and refill the transmission with clean, fresh fluid

.

2.5.1.2 Linkage and Band Adjustment

The types of linkages found on an automatic transmission are gearshift selection and

throttle kickdown. The system can be a cable or a series of rods and levers. These

systems do not normally present a problem, and preventive maintenance usually

involves only a visual inspection and lubrication of the pivot points of linkages or the

cable. When adjusting these linkages, you should strictly adhere to the manufacturer's

specifications.

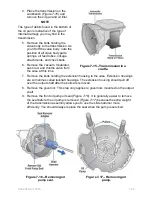

If an automatic transmission is being used in severe service, the manufacturer may

suggest periodic band adjustment, as shown in

Figure 7-12

. Always adjust lockup

NAVEDTRA 14050A

7-15