2.5.3 verhaul

Because of the complexity of automatic transmissions, the need for special tools, and

personnel skills, in overhauling these major components is usually done at a

Construction Equipment Department located at a Construction Battalion Center.

Overhaul of automatic transmissions is not a job for an inexperienced person. If the job

must be performed in the field, it is recommended that only a highly capable mechanic

be assigned to this type of work.

NOTE

Before proceeding with automatic transmission disassembly or reassembly, get the

applicable repair instructions and have them on hand.

Read this information carefully

and completely!

Incorrect disassembly procedures can lead to severe parts damage,

causing unnecessary equipment downtime.

Have a workplace away from the main CM shop. A dust-free air-conditioned room is the

best, but this is not always available. Obtain the cleanest work space possible! Have on

hand any special tools needed for the job, such as snap ring pliers, torque wrenches, or

special pullers. It is also a good idea to have an air compressor available for test

purposes and for blowdrying individual parts. The steps listed below are common

procedures listed for a generic automatic transmission and may not follow the type you

are working on.

CAUTION

Compressed air used for cleaning purposes should not exceed 30 psi. Wear goggles

and other appropriate protective equipment when you use compressed air

.

1. Clean the outside of the transmission and drain out as much fluid as possible.

2. Remove the torque converter and set it aside for separate cleaning and testing.

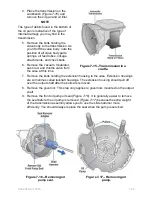

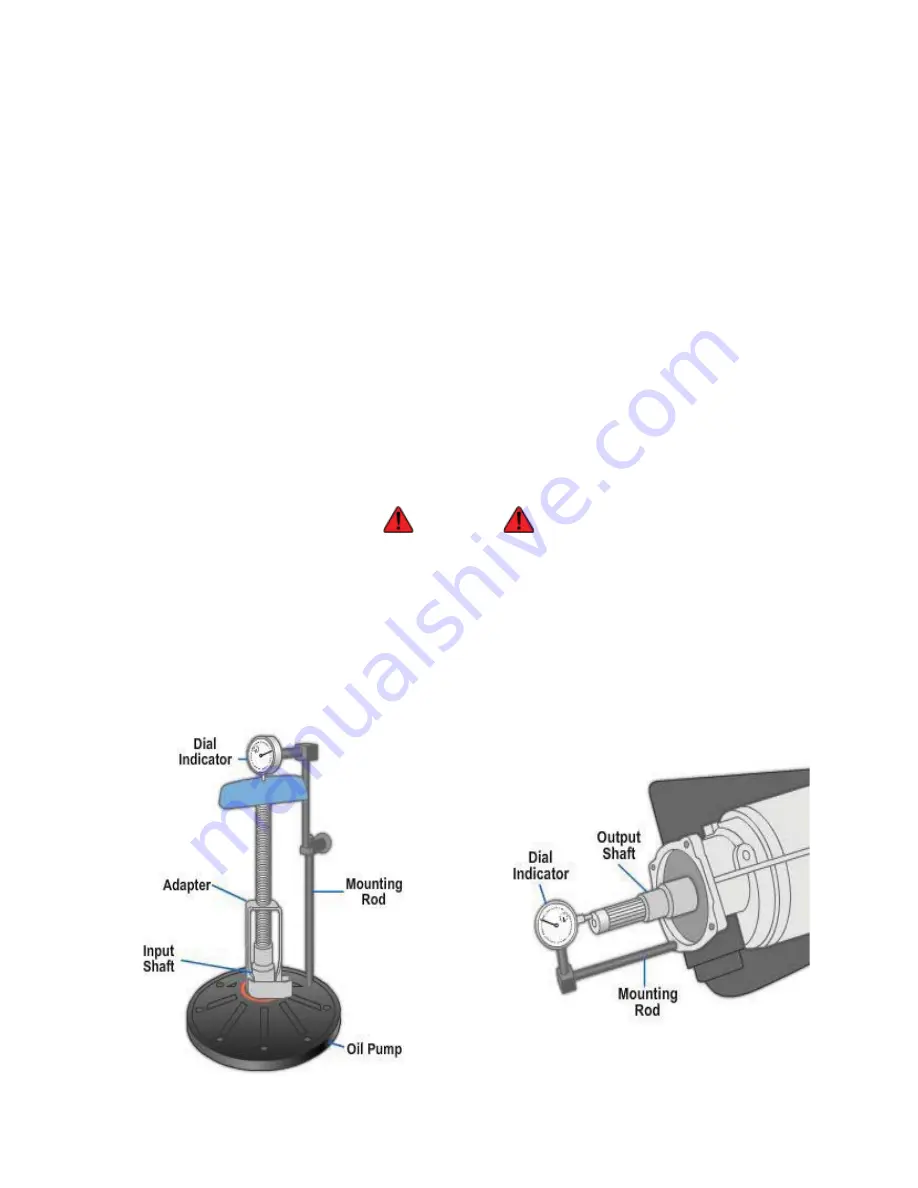

3. Check the input (

Figure 7-13

) and output (

Figure 7-14

) shaft endplay. This should

be checked before disassembly and after reassembly. Record the endplay

readings for later reference.

Figure 7-13 - Checking input

shaft endplay.

Figure 7-14 - Checking output

shaft endplay.

NAVEDTRA 14050A

7-19