Next, use a dummy shaft or

arbor shaft (shaft tool designed

for driving) to drive out the

counter shaft and reverse idler

shaft.

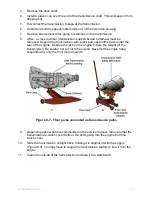

Now you can remove the input

shaft and the output shaft

assemblies. Slide the output

shaft and gears out of the back

or top of the transmission as a

unit. Be careful not to nick the

gears on the case (

Figure 8-10

)

.

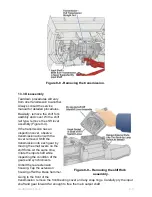

1.3.4 Cleaning and Inspecting

Disassembly

With all of the parts removed

from the case for metal shavings,

inspect them closely. First, check

inside the case for metal

shavings. If brass-colored

particles are found, one or more

of the synchronizers or thrust

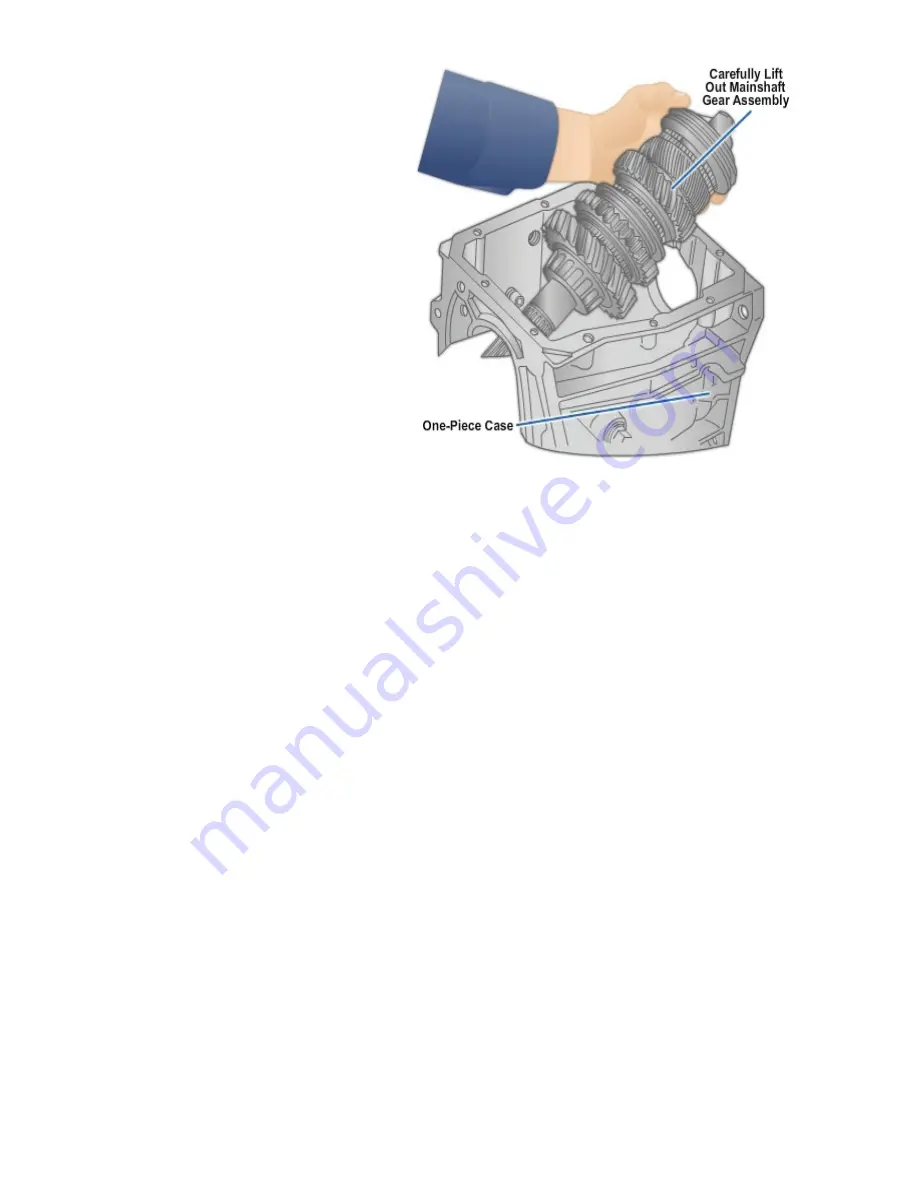

Figure 8-10 - Removing the mainshaft

washers are damaged. These are normally the only parts in the transmission made of

this material.

If iron chips are found, the output drive gears are probably damaged. After checking the

case, clean the inside with solvent. Then blow it dry with compressed air while wearing

eye protection. Also clean the transmission mission bearings.

Next, inspect all of the output gears. Look for wear patterns or chips on the gear teeth.

The gears are usually case-hardened. If wear is more than a few thousandths of an

inch, the hard outer layer will be worn through, and the gear must be replaced.

Transmission shaft runout is the amount of wobble produced when a bent or worn shaft

is rotated. If gear tooth wear is uneven, check the shaft bearings and shafts. They may

be worn or bent. A dial indicator can be used to check the transmission shafts for

straightness. Refer to specifications for the amount of allowable runout.

Inspect the synchronizer assemblies, especially if the transmission had gear shift

problems (

Figure 8-11

). Check the teeth, splines, and grooves on the synchronizers.

Replace parts as needed.

View A

shows all the components of the assembly.

View B

shows basic synchronizer components.

View C

shows checking shift forks and

synchronizers for wear.

View D

illustrates inspect ridges inside the blocking ring.

8-18

NAVEDTRA

14050A