1.3.5 Replace Worn or Damaged Parts

Any worn or damaged part in the transmission must be replaced. This is why your

inspection is very important. If any trouble is not corrected, the transmission rebuild may

fail. You would have to complete the job a second time.

It is generally recommended to always replace all gaskets and seals in the

transmission. Even though a seal or gasket might not leak before teardown, it could

start to leak after assembly.

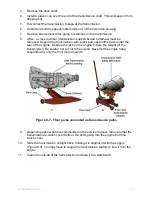

Figure 8-12

shows a typical way of replacing a rear seal.

The rear seal can be removed and installed with the transmission still in the vehicle.

View A

shows the seal being removed and

View B

shows driving in a new seal. Coat

the outside of the new seal with non-hardening sealer before installing.

Figure 8-12 -

Replacing the oil seal.

When replacing a gear on the output

shaft, you should also replace the

matching gearset on the countershaft.

If a new gear is meshed with an old

worn gear, gear noise can result.

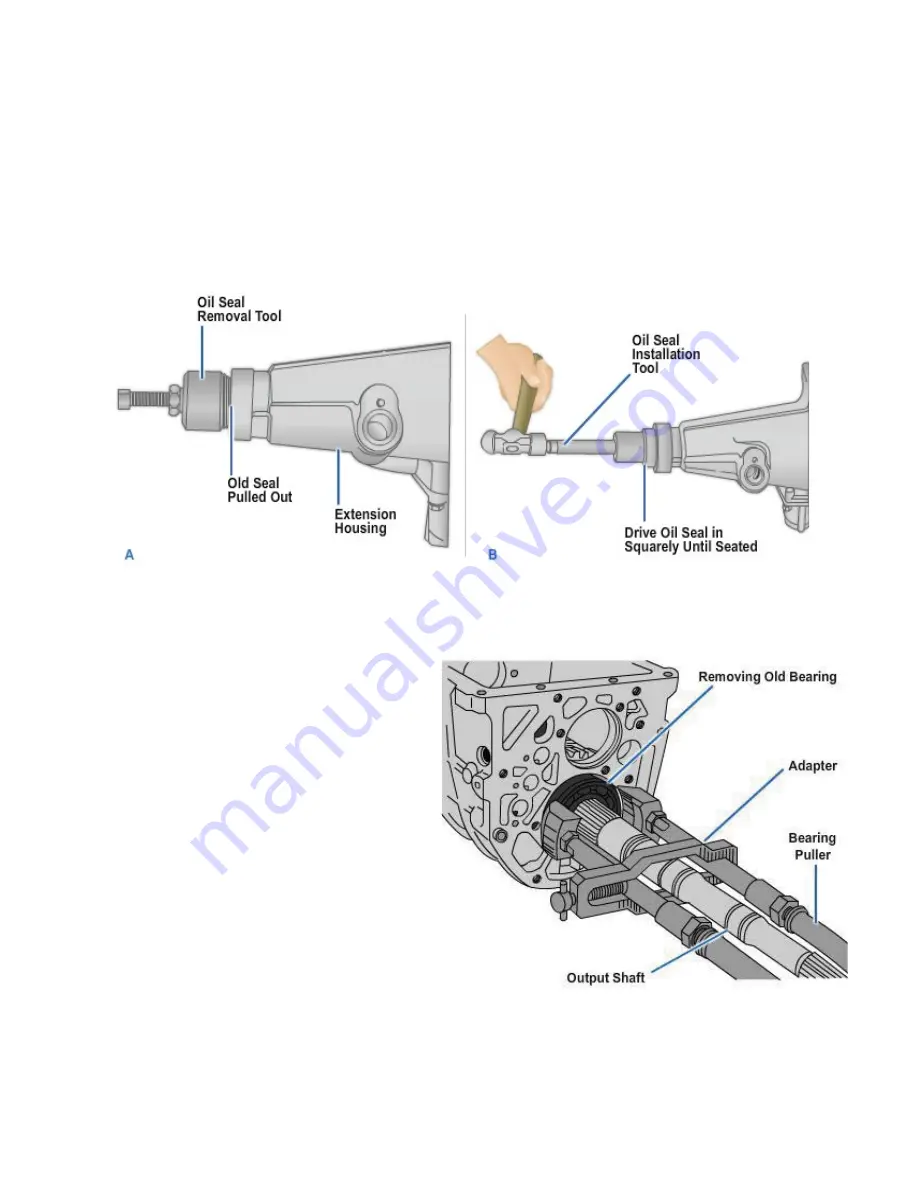

Frequently, you will need to replace

input shaft bearings. These bearings

are prone to wear because they

support a great amount of load. You

can turn by hand to feel signs of wear

or unevenness. A special puller may

be needed to remove some bearings

(

Figure 8-13

).

1.3.6 Reassembly

After obtaining new parts to replace

the old worn ones, you are ready for

reassembly. Typically, the

transmission is assembled in reverse

order of disassembly. Again, refer to

the service manual for detailed

procedures for reassembly.

The service manual will usually have

Figure 8-13 - Removing bearings with

puller.

exploded views of the transmission (

Figure 8-14

) and assemblies (

Figure 8-15

). They

8-20

NAVEDTRA

14050A