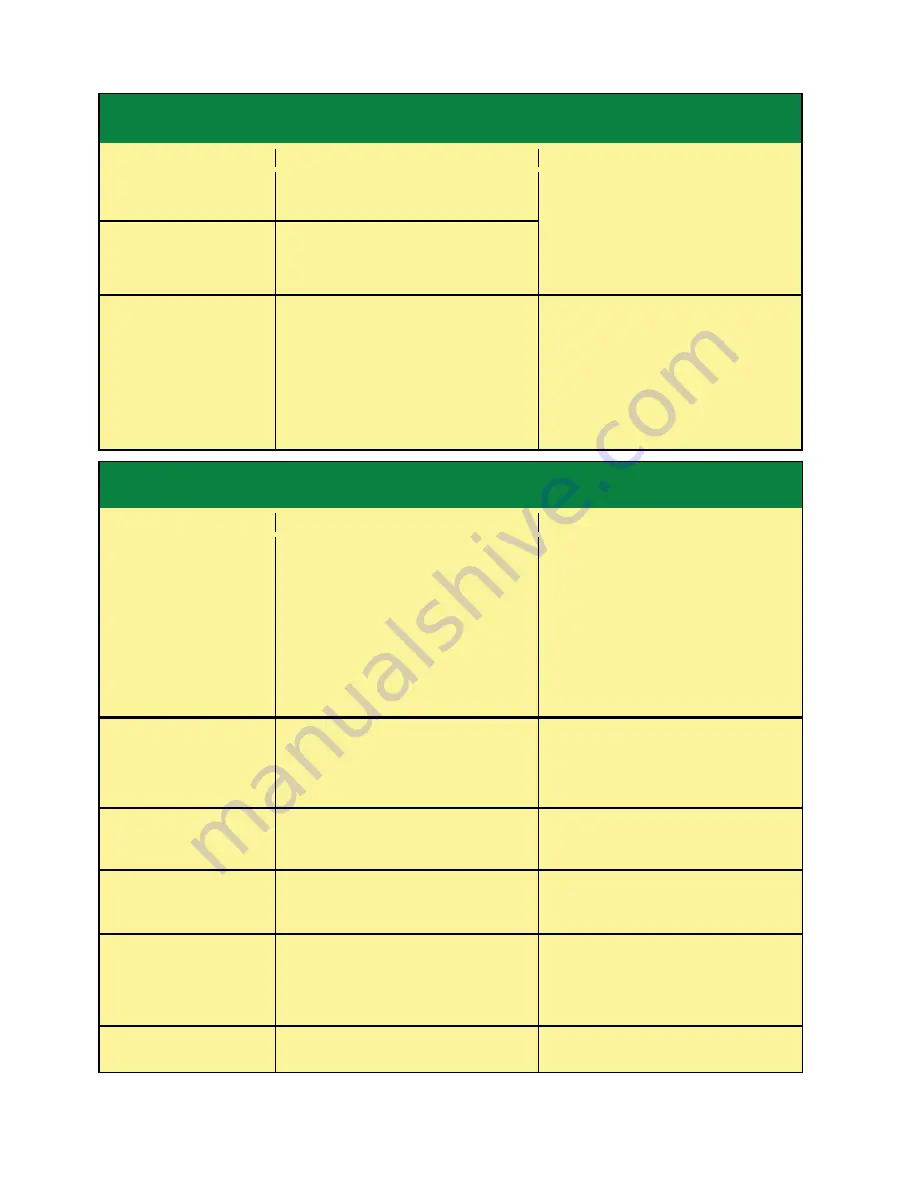

Transfer Case Diagnosis

Part-Time Drive

Condition

Possible causes

Correction

Jumps out of gear in two-

wheel drive.

1.

Shift lever detent spring weak or broken.

2.

Sliding clutch spline engaging surface

worn or tapered.

1.

Replace spring.

2.

Replace worn parts.

Noise.

Note: Transfer cases using a

gear drive produce

considerable gear whine,

which is normal.

1.

Worn bearings, splines, chipped gears,

or worn shafts.

2.

Low lubrication level.

3.

Loose or broken mounts.

1.

Rebuild unit.

2.

Fill to proper level.

3.

Tighten or replace mounts.

Jumps out of gear in four-

wheel drive.

1.

Shift lever interference with floor pan.

2.

Excessive transfer case movement.

3.

Sliding clutch engaging surface tapered

or worn.

4.

Bent shift fork.

5.

Shift rod detent spring weak or broken.

6.

Shift lever torsion spring (where used)

not holding.

7.

Worn bearings, gear teeth, or shafts.

1.

Provide proper clearance.

2.

Check and replace transfer case mounts.

3.

Replace worn parts.

4.

Replace shift fork.

5.

Replace detent spring.

6.

Replace torsion spring.

7.

Overhaul unit.

Transfer Case Diagnosis

Full-Time Dive

Condition

Possible causes

Correction

Noisy operation.

1.

Low lubrication level.

2.

Operating in "lockout" on hard, dry

surface roads.

3.

Improper lubricant.

4.

"Slip-stick" condition. Makes a grunting,

pulsating, rasping sound.

5.

Excessive wear on gears, chains, or

differential unit.

6.

Loose or deteriorated mounts.

1.

Fill to correct level.

2.

Shift out of "Lockout." Advise driver.

3.

Drain and fill with recommended

lubricant.

4.

Normal if vehicle has been driven for a

week or two. Should stop after some

usage. If it persists, drain fluid and refill.

Use special additive, if required. Make

certain tire sizes are the same and

pressures are equal

5.

Rebuild as needed.

6.

Tighten or replace.

Jumps out of low range

and/or is hard to shift into or

out of low range.

1.

Shift linkage improperly adjusted, bent,

or broken.

2.

Shift rails dry or scored.

3.

Improper driver operation.

4.

Reduction unit parts worn or damaged.

1.

Adjust correctly. Straighten or replace.

2.

Clean, polish. Or lubricate or replace as

needed.

3.

Follow shift procedure recommended by

manufacturer.

4.

Repair as needed.

Lockout will not engage.

1.

Lockout parts damaged.

2.

Defective vacuum control. Loose or

damaged vacuum lines.

3.

Defective shift linkage.

1.

Repair as needed.

2.

Replace control. Replace or connect

vacuum hoses.

3.

Repair or replace.

Will not engage in two-wheel

drive.

1.

No vacuum. Loose or broken hoses.

2.

Defective shift motor (axle).

3.

Defective shift motor (transfer case).

1.

Replace hoses. Secure all loose

connections.

2.

Replace shift motor.

3.

Replace shift motor.

Will not engage in four-wheel

drive.

1.

No vacuum. Loose or broken hoses.

2.

Defective axle shift motor.

3.

Binding or broken transfer case shift

linkage.

4.

Defective axle shift linkage.

5.

Damaged transfer case.

1.

Replace hoses. Secure all loose

connections.

2.

Replace shift motor.

3.

Repair or replace shift linkage.

4.

Repair or replace shift linkage.

5.

Repair or replace transfer case.

Vehicle wanders when driving

straight ahead.

1.

Improperly matched tire size.

2.

Uneven tire pressure.

1.

Use a matched set of tires.

2.

Adjust air pressure to recommended

levels.

Figure 8-24 - Transfer case quick reference troubleshooting guide.

NAVEDTRA 14050A

8-34