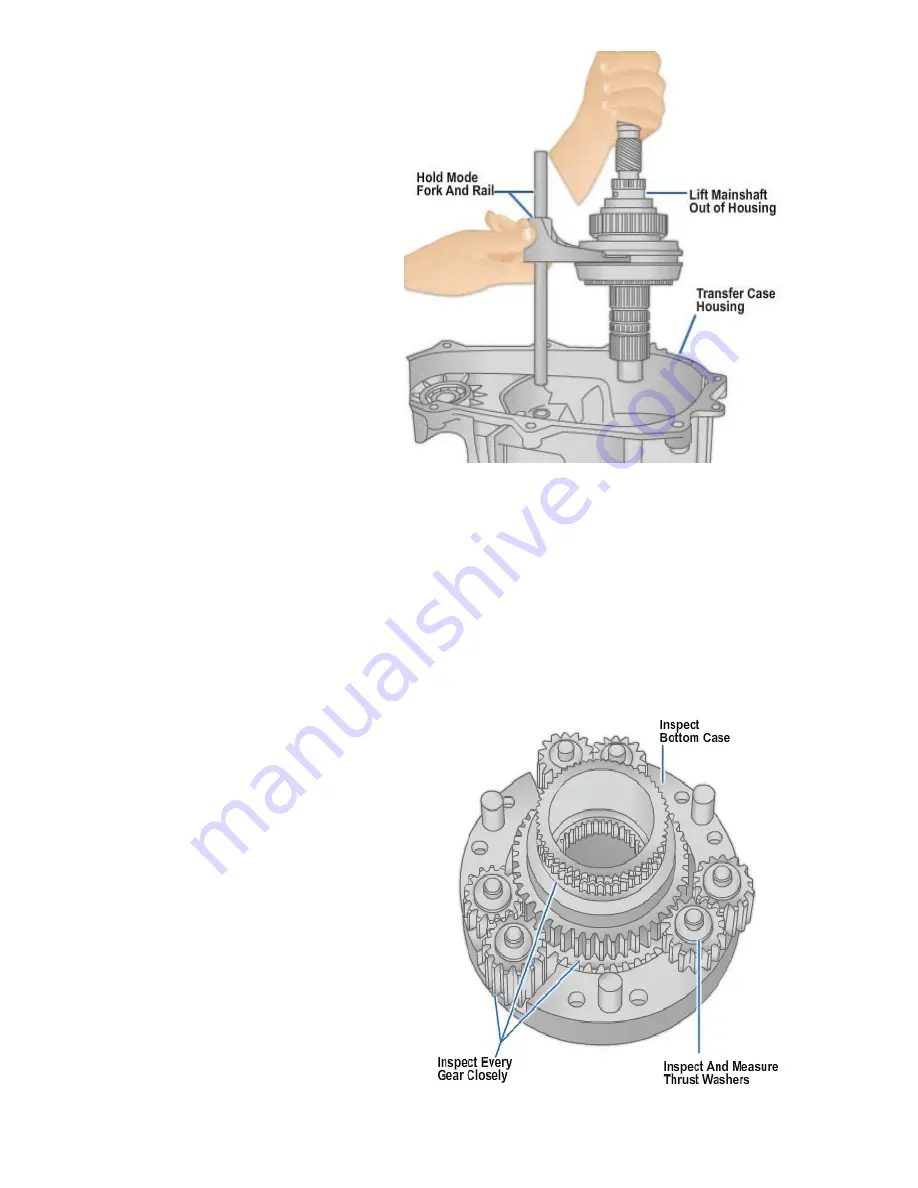

Figure 8-28

shows a mechanic

removing a mainshaft, complete

with gears, shift fork, and rail.

Removal procedures for other

parts are similar. Some transfer

cases do not have an input shaft.

Instead, the transmission output

shaft is splined to the inside of

the transfer case input gear.

Remove the differential unit,

viscous coupling, or clutch drum

as applicable.

If the transfer case is equipped

with a drive chain, lift the front

output shaft, sprocket, and chain

out of the case. In many transfer

cases, the chain and sprockets

are removed as an assembly. In

some designs, however, it is

necessary to slide the chain off

the mainshaft drive sprocket

during the removal process. After

removing the chain and

Figure 8-28 - Removal of mainshaft,

complete with gears, shift fork, and rail.

sprockets, carefully remove any thrust washers that were located under the sprocket.

While disassembling the transfer case, note the relationship of all parts so that they can

be reinstalled properly. If necessary, mark the parts with a punch or a scribe to ensure

proper assembly.

2.2.3 Transfer Case Inspection

Before inspecting the transfer

case parts, scrape all gasket

material from the transfer case

housing, being careful not to

damage the surfaces. Check the

bottom of the housing for needle

bearings or other small parts.

Clean the inside of the housing

and all internal parts. Make sure

all sludge and metal particles are

removed.

After cleaning, thoroughly inspect

the transfer case housing,

bearing retainers, and extension

housings for cracks or other

damage. Additionally, check all

bushings and seals for wear.

All internal transfer case parts

should be inspected for wear and

damage. Examine all shaft

bearings, needle beatings, shift

NAVEDTRA 14050A

Figure 8-29 - Check planetary gear

assembly.

8-38