22 Installing the System Piping

WARNING

Ɣ

Immediately repair any leaks in the system plumbing

to avoid adding make-up water. Make-up water adds

oxygen and minerals to the system that may lead to heat

exchanger failure.

Ɣ

Failure to follow these instructions may result in poor

performance, unnecessary wear of system components

and premature failure.

CAUTION

Do not solder piping directly onto the water connections,

as the heat may cause damage to internal components. Use

threaded water connections only.

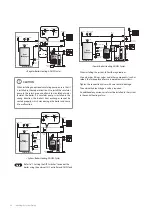

4.1.2 Essential Elements in a Central Heating

System

Auto Air Vent

The LCB700 boiler is equipped with an automatic air vent so that

the air from the boiler is automatically discharged. A separate

automatic air vent must be installed at the top of the piping

system to exhaust air from the entire piping system.

Expansion Vessel

An expansion vessel must be installed in the central heating

piping to prevent excessive pressure from building up in the

system.

The expansion vessel must be sized in accordance with the

water volume of the system as well as the firing rate of the

appliance.

Note

Ensure that the expansion vessel used is of sufficient

size for the system volume. Refer to BS 7074:1:1989

or The Domestic Heating Design Guide for sizing the

required vessel.

It is important to locate the expansion vessel and make-up

water connection, on the inlet side of any pump in the system,

as doing so will guarantee the lowest pressure in the system will

be at least equal to the vessel and make-up water pressure.

CAUTION

Ensure the expansion vessel cannot become isolated from

the boiler anytime the system is operating. Failure to follow

these instructions may lead to discharge from the pressure

relief valve, which may result in property damage or injury.

Pressure Relief Valve

The requirements recommended for the pressure relief valve are

as follows:

Ɣ

The pressure relief valve is calibrated to be activated at a

maximum pressure of 3 bar, and all the pipes and connections

must therefore be able to withstand pressures of up to 3 bar.

Ɣ

It must tilt in a downstream direction throughout its entire

length, and the water must run off to a suitable drain. It must

be positioned so as not to cause damage to cabling, electrical

equipment or persons.

Ɣ

The pressure relief discharge pipe must not be located above

a window, entry door or any other public access point. Bear

in mind that boiling water or steam could come out when

operating.

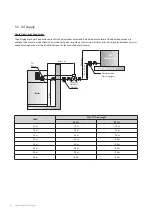

4.1.3 Central Heating System Piping

When connecting the central heating system, follow these

guidelines:

Ɣ

Carefully tighten all connections to avoid damage to fittings.

Ɣ

After installing the boiler, check the central heating system's

operation and inspect for leaks.

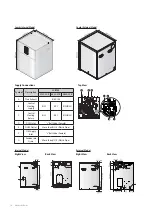

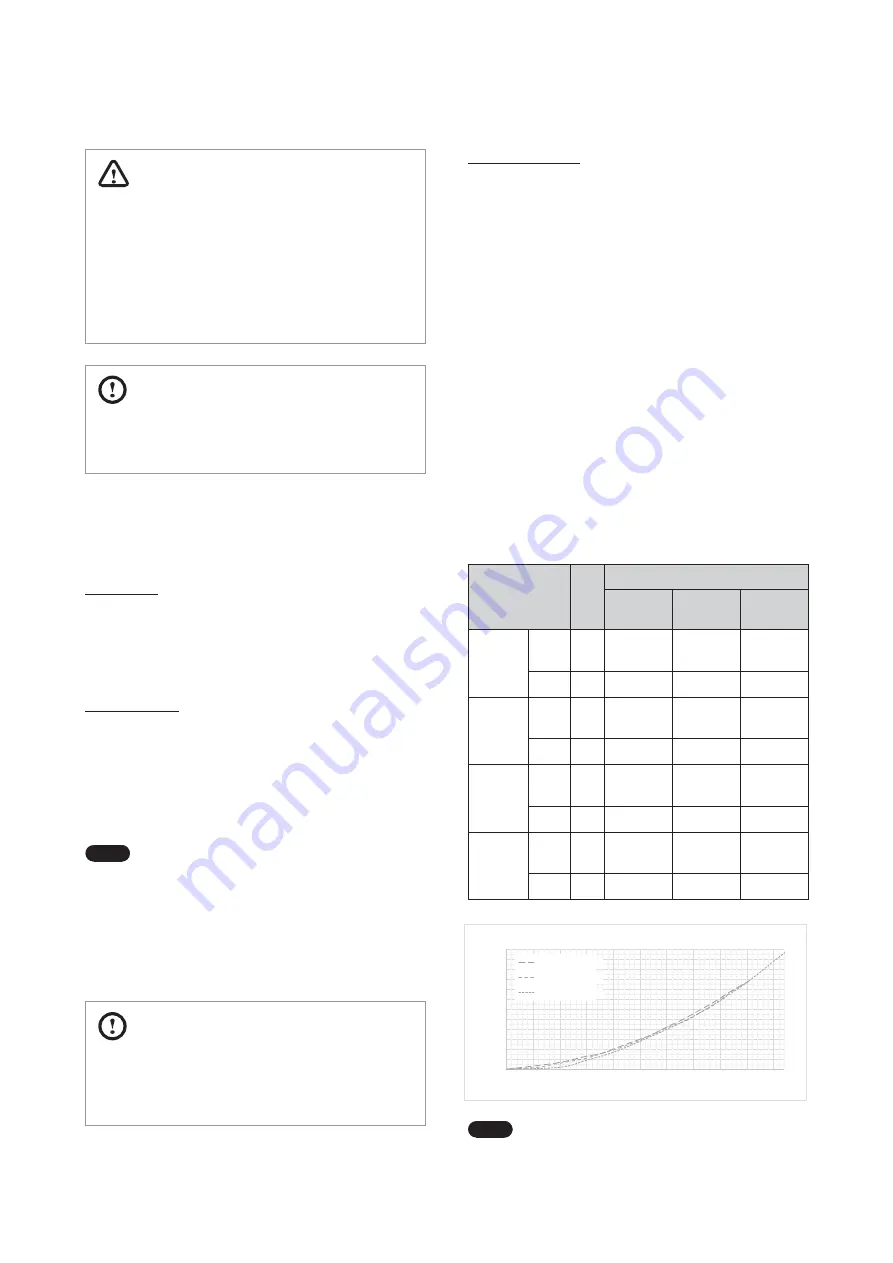

Items

Unit

Model

21RS/RSX

21LS/LSX

28RS/RSX

28LS/LSX

36RS/RSX

36LS/LSX

ڹ

t 10°C

Flow

Rate

lpm

30.1

40.1

51.6

Head

m

4.3

7.0

11.1

ڹ

t 15°C

Flow

Rate

lpm

20.1

26.8

34.4

Head

m

2.1

3.5

5.2

ڹ

t 20°C

Flow

Rate

lpm

15.1

20.1

25.8

Head

m

1.2

2.0

3.0

ڹ

t 25°C

(Minimum)

Flow

Rate

lpm

12

16

20

Head m

0.9

1.2

1.7

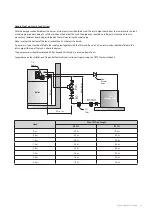

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

0

5

10

15

20

25

30

35

40

45

50

ǻ

P [

b

a

r]

Flow [LPM]

.%$2TGUUWTG&TQR

LCB700 21K_Set

LCB700 28K_Set

LCB700 36K_Set

21 kW

28 kW

36 kW

Note

Refer to the performance curve to select a pump

that suits your application. The boiler can supply up

to a maximum of 100 W current at the boiler pump

connection terminal.

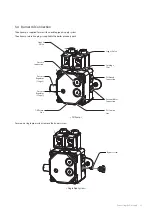

Summary of Contents for LCB700-21LC

Page 78: ...78 Appendices 13 2 2 Burner Cover Flame Tube...

Page 92: ...Memo...

Page 93: ...Memo...

Page 94: ...Memo...

Page 95: ......