Installing the System Piping 23

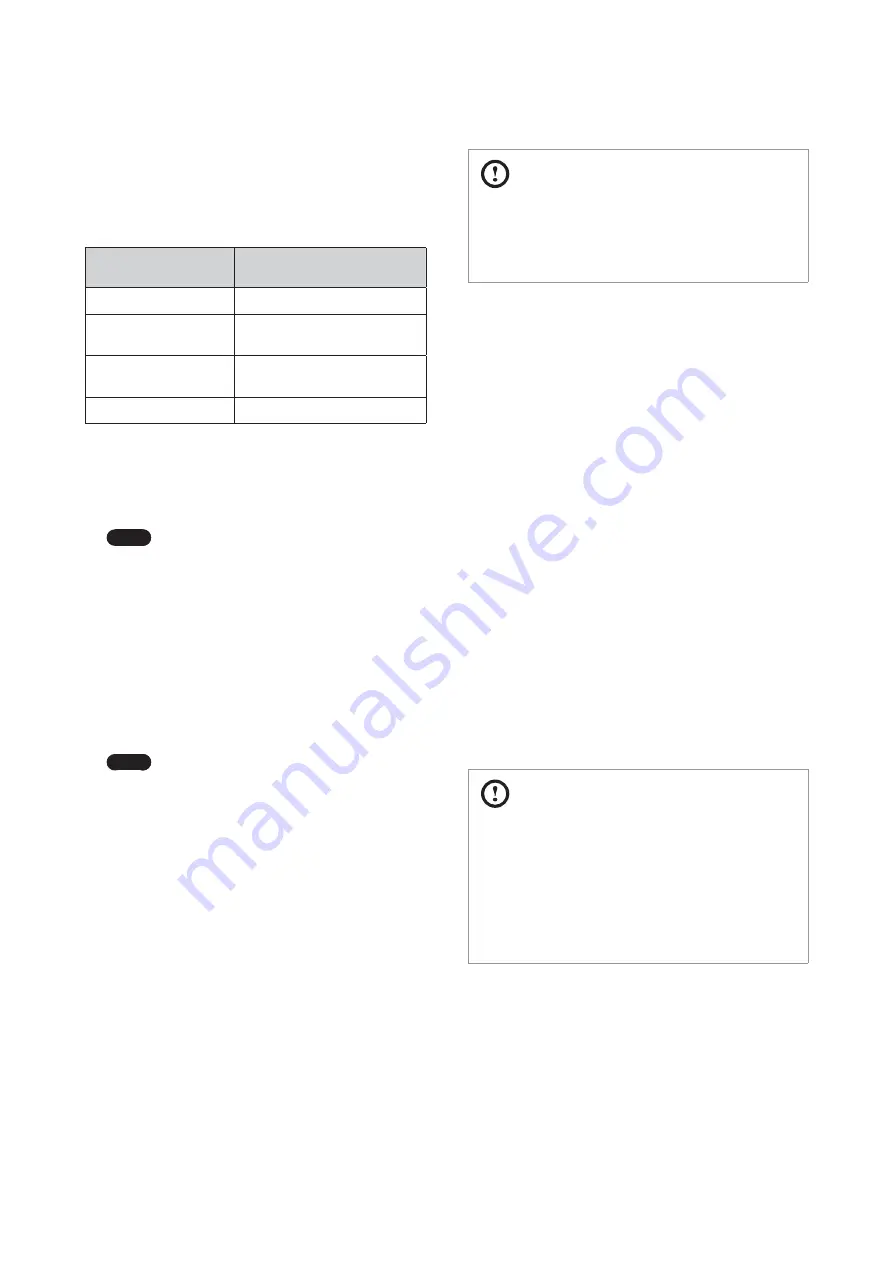

4.1.4 Water Quality Standards for Appliance

Quality Assurance

The water supplied to the boiler must satisfy the water quality

requirements on the following table.

Water Chemistry

Standards for Appliance Quality

Assurance

+DUGQHVV

Below 200 ppm

Chloride Concentration

Below 150 ppm

(Below 4 ppm of residual chlorine)

TDS

(Total Dissolved Solids)

Below 500 ppm

pH

6.5–8.5

Ɣ

The water hardness must be below 200 ppm.

Using water with a hardness above 200 ppm for the boiler

may create lime scale inside the boiler and cause a product

malfunction. Use a water softener to satisfy the standards for

appliance quality assurance (below 80 ppm is recommended).

Note

Using indirect heat exchange through a plate-

type heat exchanger is an exception.

Ɣ

The chloride concentration of water must be below 150

ppm (below 4 ppm of residual chlorine).

Using the water with a chloride concentration above 150

ppm or 4 ppm for residual chlorine for the boiler may cause a

product malfunction due to corrosion.

Ɣ

The pH must be between 6.5 and 8.5.

-

Using water with a pH below 6.5 may cause a product

malfunction due to corrosion.

-

Using water with a pH above 8.5 may cause a product

malfunction due to lime scale created inside the boiler.

Note

The following situations adversely impact the

quality of the appliance

Ɣ

The water supplied to the boiler does not satisfy the water

quality requirements in the table above.

-

Using chemically unbalanced water for the boiler may

cause a product malfunction or reduce the product

lifetime.

Ɣ

Water below the minimum circulation flow rate is supplied

to the boiler (to see detailed flow rate information, refer to

the “4.1.3 Central Heating System Piping” on page 22.

-

Using water that is below the minimum circulation flow

rate for the boiler may cause a product malfunction due to

the creation of lime scale inside the boiler or a reduction

in product efficiency. If the flow rate is lower than the

minimum rate, use an external pump (below 100 W) to

maintain a flow rate above the minimum. Also, ensure the

pipes used for the boilers are not blocked and check if

there are any pressure drops.

CAUTION

If the water supplied to the boiler does not satisfy the water

quality requirements, contact an authorised technician or

licensed professional to avoid product malfunctions due to

poor water quality before supplying water to the boiler.

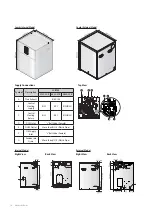

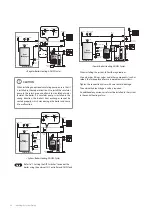

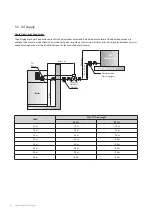

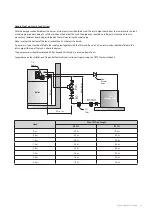

4.2 Installing a System Application

Refer to the following examples to properly implement a system

for central heating, DHW supply, or both. These examples

are provided to suggest basic guidelines when you installing

the boiler system. However, the actual installation may vary

depending on the circumstances, local building codes or

regulations.

The heating capacity of the unit must be previously established

by calculating the building’s heat requirement according to

the current regulations. To ensure proper operation and long

boiler life, the plumbing system must be adequately sized and

complete with all the necessary accessories, including a room

thermostat, a thermostatable valve (TRV), etc. The system

delivery and return pipes must have a diameter of at least 22

mm for the first 3 m of length from the unit.

If the system delivery and return pipes follow a path where air

pockets can form in certain places, it is advisable to install vent

valves at these points. Also, drain cocks must be installed at the

lowest points in the system to allow complete emptying.

An automatic bypass with a flow rate of at least 6 l/min must

be installed (as far away as possible from the boiler) if radiators

with thermostatic valves have been connected to combination

boilers and in front of any motorised valves for system/regular

boilers.

CAUTION

Ɣ

The installation must be made by sufficiently qualified

technicians, authorised to do so.

Ɣ

For correct installation, all the requirements and

recommendations described in the Regulation for

Heating Installations in Buildings (RITE) must be

complied with, together with all other national and/or

local regulations applicable at the time of installation.

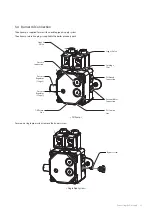

Summary of Contents for LCB700-21LC

Page 78: ...78 Appendices 13 2 2 Burner Cover Flame Tube...

Page 92: ...Memo...

Page 93: ...Memo...

Page 94: ...Memo...

Page 95: ......