Appendices 59

12.1 Gas Conversion

This boiler is configured for Natural Gas at the factory. If

conversion to Propane Gas is required, use the conversion kit

supplied with the boiler.

WARNING

This conversion kit must be installed by a qualified service

agency* in accordance with all applicable codes and

requirements of the authority having jurisdiction. The

information in these instructions must be followed to

minimises the risk of fire or explosion or to prevent property

damage or personal injury. The qualified service agency

is responsible for the proper installation of this kit. The

installation is not proper and complete until the operation

of the converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

* A qualified service agency is any individual, firm, corporation or

company which either in person or through a representative is

engaged in and is responsible for the connection, utilization, repair

or servicing of gas utilization equipment or accessories; who is

experienced in such work, familiar with all precautions required, and

has complied with all of the requirements of the authority having

jurisdiction.

Tools Required:

●

Phillips Screwdriver

●

Flathead Screwdriver

●

5

/

32

in or 4 mm Allen Wrench

●

Combustion Analyser or Dual Port Manometer

●

Gas Leak Detector

Included Items:

●

Gas Orifice (refer to below table)

Model

G20

G31

NCB700-42C

Ø4.4/Ø6.4

Ø3.65/Ø3.95

NCB700-54C

Ø4.8/Ø7.5

Ø4.0/Ø5.65

Table 1. Orifice Size

●

Gas Pressure and Conversion Kit Number Labels

Procedure:

1. Turn off both gas and water supply to the boiler.

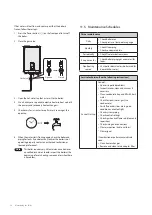

2. Unfasten the 2 latches (at the top) and remove 2 screws (at

the bottom) to remove the front cover to gain access to the

internal components. See Figure 1 for illustration of the front

cover on the unit.

Figure 1. NCB700 Series Front cover

3. Remove the front cover and place it in a safe location to

prevent accidental damage.

4. Label all the wires on the PCB.

5. Disconnect all the wires.

12. Appendices

Summary of Contents for NCB700-42C

Page 69: ...68 Appendices 12 4 Ladder Diagram 3 15A...

Page 73: ...Memo...

Page 74: ...Memo...

Page 75: ...Memo...