on the severity of the wind gusts and whether the wind turbine stays furled depends

on the wind speed.

As the wind turbine furls the geometry of the tail pivot caused the tail to lift slightly.

When the high winds subside the weight of the tail assembly returns the whole turbine

to the straight position. The AutoFurl system works whether the turbine is loaded or

unloaded.

The AutoFurl system is completely passive, so it is very reliable and since there are

no wear points, like in a mechanical brake system, it is very robust.

There is one situation in the field, however, that we have found an disrupt the

operation of AutoFurl. If the wind turbine is installed on a sharp hill or next to a cliff

so that the wind can come up through the rotor on an incline(e.g., from below; as

opposed to horizontally) we know that this will affect furling and can produce higher

peak outputs. We strongly recommend avoiding this situation.

The wind generator is designed to survive in wind speeds of up to 90mph.

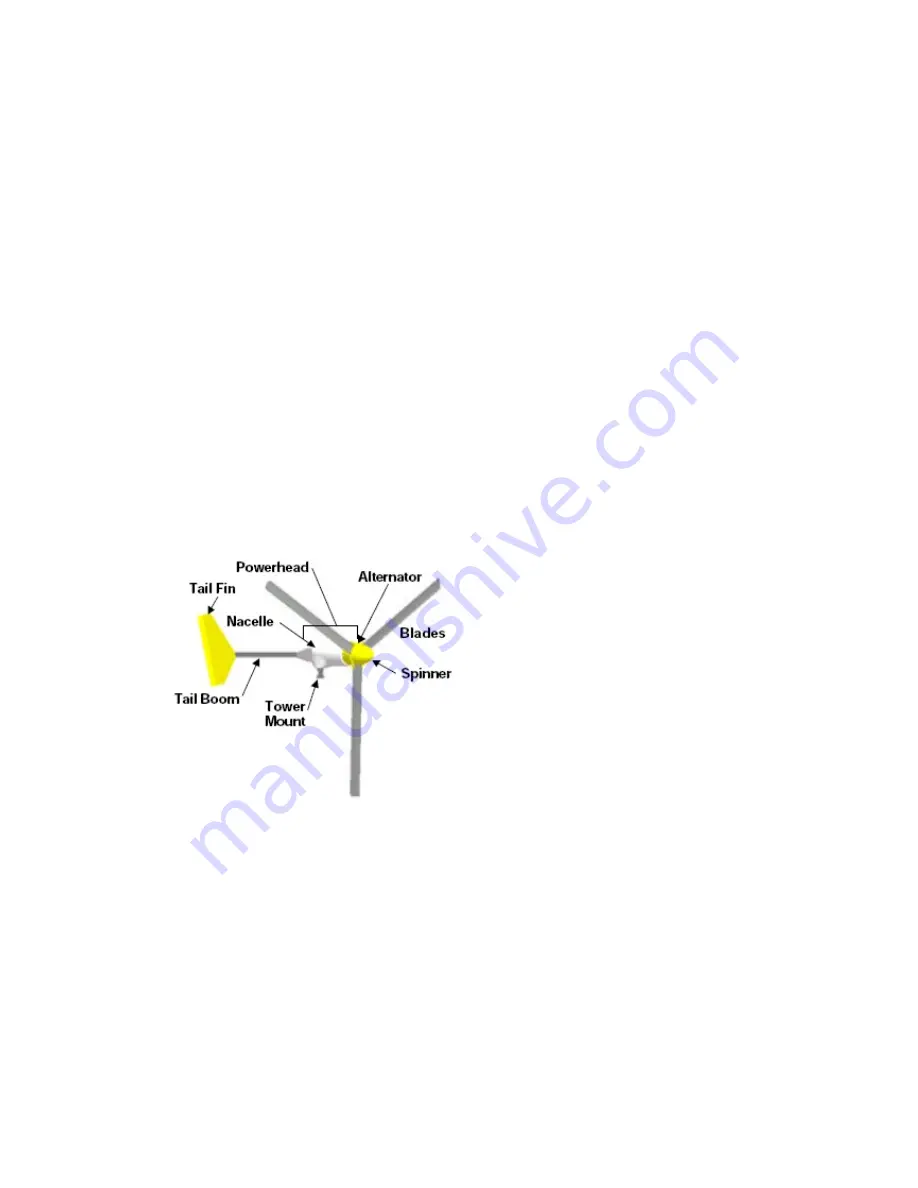

Components of Wind Energy Systems

The basic components of a typical wind energy system are shown below:

Components of a wind energy system.

These basic components include:

•

A rotor, consisting of blades with aerodynamic surfaces. When the wind blows

over the blades, the rotor turns, causing the generator or alternator in the

turbine to rotate and produce electricity.

•

A gearbox, which matches the rotor speed to that of the generator/alternator.

The smallest turbines (under 10 kW) usually do not require a gearbox.

•

An enclosure, or nacelle, which protects the gearbox, generator and other

components of the turbine from the elements.

•

A tailfin or yaw system, which aligns the turbine with the wind.

If you plan on building a horizontal axis wind turbine, you will need a tower on which

to mount the turbine (vertical axis turbines are usually built on the ground).