BWG-S

ERIES

O

PERATION

& M

AINTENANCE

M

ANUAL

12838 Stainless Drive, Holland, MI 49424

Phone: 616/399-5600 Fax 616/399-3084

Copyright 2018 BRAWN Mixer

www.BRAWNMIXER.com

Page 8 of 11

11/27/

2018

STORAGE

Units shipped from Brawn Mixer are intended to be used

within 30 days after receipt and presumed to be stored

indoors in a heated building. Store mixers as packaged

by the factory. If you intend storing units under adverse

conditions or for a long period of time, special storage

precautions will be necessary.

1. Store in a sheltered area away from chemical vapors or

steam.

2. Cover.

3. Do not store in sunlight or near high heat.

4. Spray oil on exposed shafts and seals. Remove oil on

start-up.

5. Rotate output shaft 360º every 3-4 weeks.

6. Mixers should not be stored near vibrating machinery

to avoid damage to the bearings.

7. If electric motors have been subjected to humid

conditions, check the insulation resistance between

phase and mass and between the different phases.

The resistance should not be less than 100

megohms. If the resistance is less, please consult

the factory

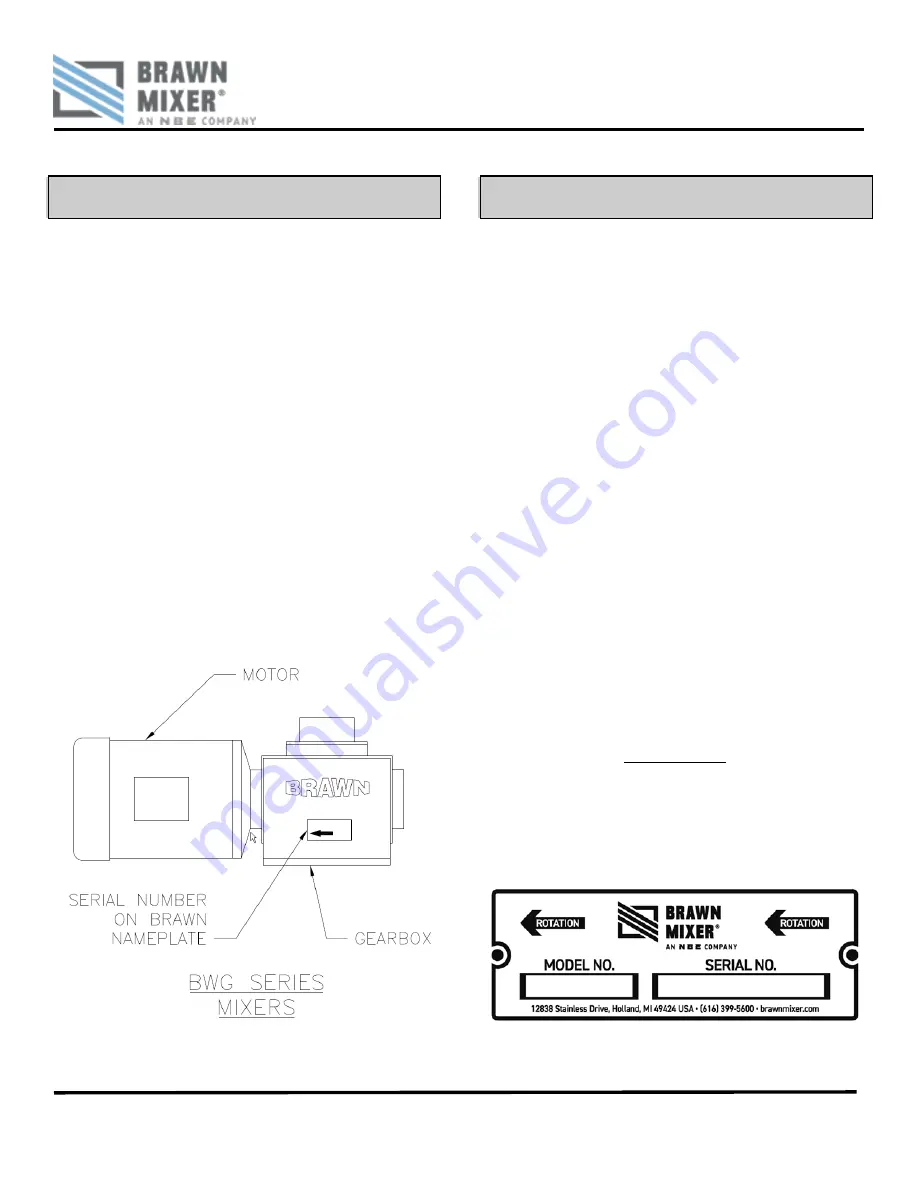

BWG GEARBOX FEATURES

[SEE FIGURE ON PAGE 9]

1.

Rugged Cast Iron Housings

provide superior

strength and rigidity.

Generous Oil Capacity

assures lower operating

temperatures and maximum gear, bearing and seal

life.

2.

Hardened and Precision-Ground Worms

are cut

integral with the shaft. High helix angles provide the

ultimate in efficiency and torque capacity.

3.

Cast Iron Bearing Covers

on the input shaft provide

greater reliability when subjected to high start-up or

reversing loads.

4.

Tapered Roller Bearings

provide greater overhung

load and thrust capability, ensuring maximum life.

5.

Chill-Cast Bronze Gears

give you the long, trouble-

free life and high quality you expect from Brawn

Mixer drives.

6.

Output Oil Seal

keeps the lubricant in, contaminants

out. Maintenance costs are reduced.

7.

Alloy Steel Output Shafts

provide extra strength for

your rugged applications.

LUBRICATION

Splash Lubrication

provides positive protection for

gears and bearings.

Splash Guards

are furnished to prevent oil from leaking

through the vent.

MIXER NAMEPLATE

Summary of Contents for BRAWN MIXER BWG Series

Page 2: ......

Page 17: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 18: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 19: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 20: ......