BWG-S

ERIES

O

PERATION

& M

AINTENANCE

M

ANUAL

12838 Stainless Drive, Holland, MI 49424

Phone: 616/399-5600 Fax 616/399-3084

Copyright 2018 BRAWN Mixer

www.BRAWNMIXER.com

Page 2 of 11

11/27/

2018

INITIAL INSPECTION

1. Upon receipt of your Brawn Mixer, check for possible

shipping damage. Report any damage immediately

to the carrier and to Brawn Mixer.

2. All Brawn Mixers are shipped with the shaft and

impeller(s) disassembled from the drive assembly.

3. Storage: Mixers should not be stored near vibrating

machinery to avoid damage to the bearings. Store

mixers as packaged by the factory. For longer

storage periods, consult factory. If electric motors

have been subjected to humid conditions, check the

insulation resistance between phase and mass and

between the different phases. The resistance should

not be less than 100 megohms. If the resistance is

less, please consult the factory. If mixer is stored for

more than a year, the condition of the gear lubricant

should be checked before the mixer is put in

operation (see lubrication instructions).

INSTALLATION

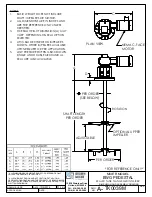

[REFER TO ASSEMBLY / DIMENSION DRAWING]

Refer to the mixer installation / assembly drawing for

important mounting structure design, assembly,

mounting and dimensional data.

1. Install the mixer drive on the mounting structure and

secure with properly-sized, Grade 5 or better

hardware. Torque the hardware as recommended in

TABLE 1

.

2.

Install mixer shaft and impeller(s) (refer to shaft and

impeller assembly section).

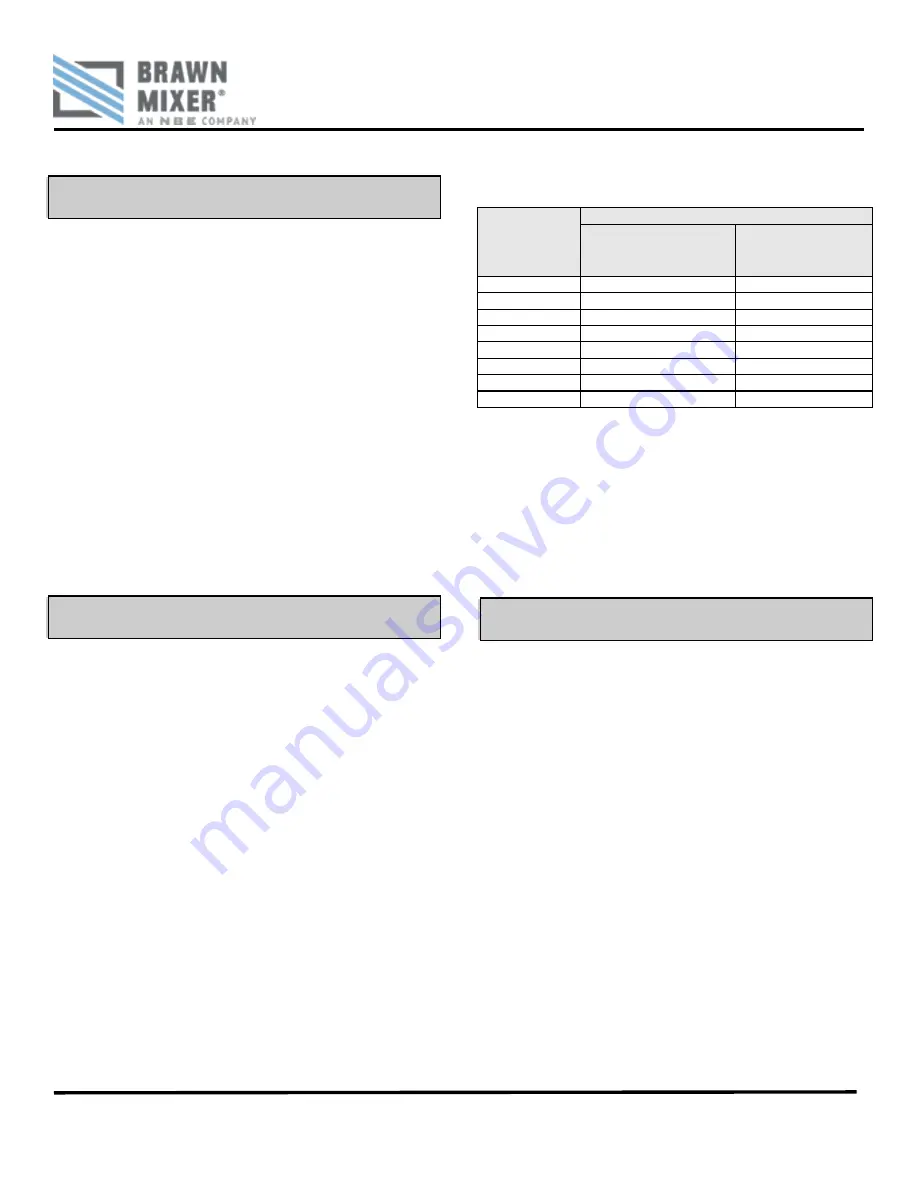

TABLE 1: RECOMMEND TORQUE VALUES

HARDWARE

SIZE

TORQUE VALUES (FOOT POUNDS)

STANDARD GRADE 2

& 300 SERIES

STAINLESS

HIGH STRENGTH

GRADES 5 & 8

3/8-16

17

27

7/16-14

27

40

1/2-13

40

65

9/16-12

65

90

5/8-11

85

125

3/4-10

135

225

7/8-9

145

365

1-8

210

545

BOLT-TIGHTENING RECOMMENDATIONS:

Inadequately or improperly tightened hardware can

loosen, due to vibration during mixer operation. This can

result in reduced mixer life or damage to equipment.

Recommended torque values for tightening all in-tank

and mounting hardware are listed in

TABLE 1

. These

average torque values should be considered only as a

guide and not as absolute values.

SHAFT & IMPELLER ASSEMBLY

If an optional rigid shaft coupling is furnished, connect

the mixer shaft and rigid driveshaft couplings by carefully

engaging the shaft rabbeted faces and installing the

mounting hardware. Be careful not to damage the

coupling faces or rabbets, as this can cause excessive

shaft run-out that will affect the life of the mixer

Proper hollow output shaft installation is shown in

FIGURE 1, PAGE 3

.

1. Inspect the shaft surface for evidence of damage

and repair, if required, before installing the shaft into

hollow output shaft or connecting to flanged

coupling.

2. Attach the shaft collar (Item 5) to the mixer shaft

(Item 4).

3. Place the key (Item 7) on the mixer shaft and slide

the mixer shaft into the hollow output shaft on the

gear drive (Item 1).

Summary of Contents for BRAWN MIXER BWG Series

Page 2: ......

Page 17: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 18: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 19: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 20: ......