AUTOMATIC LUBRICATOR

RETAIN FOR FUTURE USE

U45250 - 3 of 3

www.nord.com/docs

01.31.17

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378

Grease Purge and Grease Drain Cup

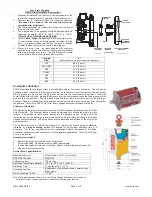

Some versions of the NEMA (or IEC) adapters also include a

grease purge and a grease drain cup (1299) for collecting old

grease. The grease purge area is sealed for transportation.

It is recommended that the G1/4 sealing screw (1297) be re-

moved and that the grease drain cup be installed after the

automatic lubricant dispenser is activated.

The swivel fitting (1242) that NORD supplies allows the grease

cup to be positioned at a 90

°

angle from its typical mounting.

The swivel fitting allows the grease cup to be rotated so that

it remains clear of any gear unit mounting obstructions.

Figure 3 – Grease Purge and Grease Cup Assembly

1311

1200

1243

1298

1299

1297

G1/4

1242

1200

NEMA or IEC Input Cylinder

1242

Swivel Fitting (P/N) 22006359)

1243

Extension*

1297

Screw Plug

1298

Seal Ring*

1299

Grease Drain Cup (P/N 2830100)

1311

Bearing

* Supplied on certain input assembly sizes as needed.

Remove the screw plug to install either the grease drain

cup or the swivel fitting with the grease drain cup.

Grease Cup Servicing

NORD suggests that with every second replacement of the

automatic lubricator, the grease collection cup (NORD Part

No. 28301210) should be emptied or replaced with a new

one. Follow the steps below to service the grease cup.

1. Unscrew the grease drain cup (1299) from either the

outlet port of the NEMA or IEC input cylinder or from the

extension (1243) that is secured to the NEMA or IEC

input cylinder.

2. To empty the grease drain cup (1299) insert a stiff rod

through the hole in the grey cap-end of the drain cup

and push the internal plunger towards the thread-end

of the drain cup. Please note that the dark gray end cap

is bonded into place and cannot be removed.

3. Collect and properly dispose of the grease being pushed

out of the drain cup. Due to the design of the container

a residual amount of grease may remain in the container.

4. After emptying and cleaning the grease cup it can be

fitted back onto the grease outlet port of the NEMA or

IEC adaptor.

5. In the event the grease cup becomes damaged or it

should be replaced with a new container. Consider

replacing the grease cup (P/N 2830100) with every

second replacement of the automatic lubricator.

Replacing the Automatic Lubricator

A new automatic lubricator can be ordered from NORD by

specifying the appropriate Part Number from the table at

the bottom of Page 1 of this manual. Reference Figure 2 and

follow the steps below to replace the automatic lubricator.

1. Loosen and remove the M8x16 socket head cap screws

(1251) holding the protective cover (1252) in place.

2. Unscrew the automatic lubricator (1250-1) from the

bearing cover area of the NEMA or IEC input cylinder.

3. Install the new automatic lubricator and activate per the

instructions on page 2.

4. Re-install the protective cover (1252) and the assembly

screws (1251).

5. Note the activation date of the newly installed automatic

lubricator

Summary of Contents for BTR Series

Page 2: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 4: ......

Page 27: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 28: ......