BTR-S

ERIES

O

PERATION

& M

AINTENANCE

M

ANUAL

12838 Stainless Drive, Holland, MI 49424

Phone: 616/399-5600 Fax 616/399-3084

Copyright 2018 BRAWN Mixer

www.BRAWNMIXER.com

Page 3 of 9

11/27/2018

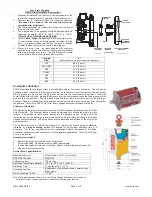

SHAFT & IMPELLER ASSEMBLY

To install the impeller on the shaft, slide the impeller hub

over the mixer shaft, place the hook key in position,

lower the hub over the hook key and tighten the set

screw. The set screw must seat in the countersunk hole

in the hook key. Proper impeller mounting is illustrated in

FIGURE 1

. If an axial flow impeller of bolt together

construction is used, blades should be bolted to the

bottom of the impeller hub ears as shown in

FIGURE 2

.

FIGURE 1: IMPELLER MOUNT WITH HOOK KEY

FIGURE 2: TYPICAL AXIAL FLOW

IMPELLER ASSEMBLY (A45 SHOWN)

START UP

1. All units are lubricated before shipment. The

lubricant level should be checked with the unit

mounted in its correct operating position. Lubricant

should be added or removed to bring it to the correct

level. The catalog for the gear unit shows the oil level

for various mounting positions.

2. Connect the motor in accordance with the motor

nameplate. The motor starter should incorporate

overload protection. Before operating the mixer, jog

the motor and observe mixer shaft rotation. Proper

rotation is clockwise, as viewed from the top, unless

otherwise noted.

3. Check all bolts and fasteners for tightness. It is good

maintenance practice to recheck all bolts after two

weeks of operation and periodically thereafter. Refer

to

TABLE 1

for recommended torque values.

4. Do not attempt to start mixer with impellers buried in

solids or solidified liquids.

CAUTION

Do not operate mixer with the tank empty or the lowest

impeller submerged with less than ½ of the impeller

diameter of liquid above it. Damage to the mixer and/or

mounting structure may result.

Summary of Contents for BTR Series

Page 2: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 4: ......

Page 27: ...THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 28: ......