7156 Service Guide

Appendix B: Communication Information

September 1998

171

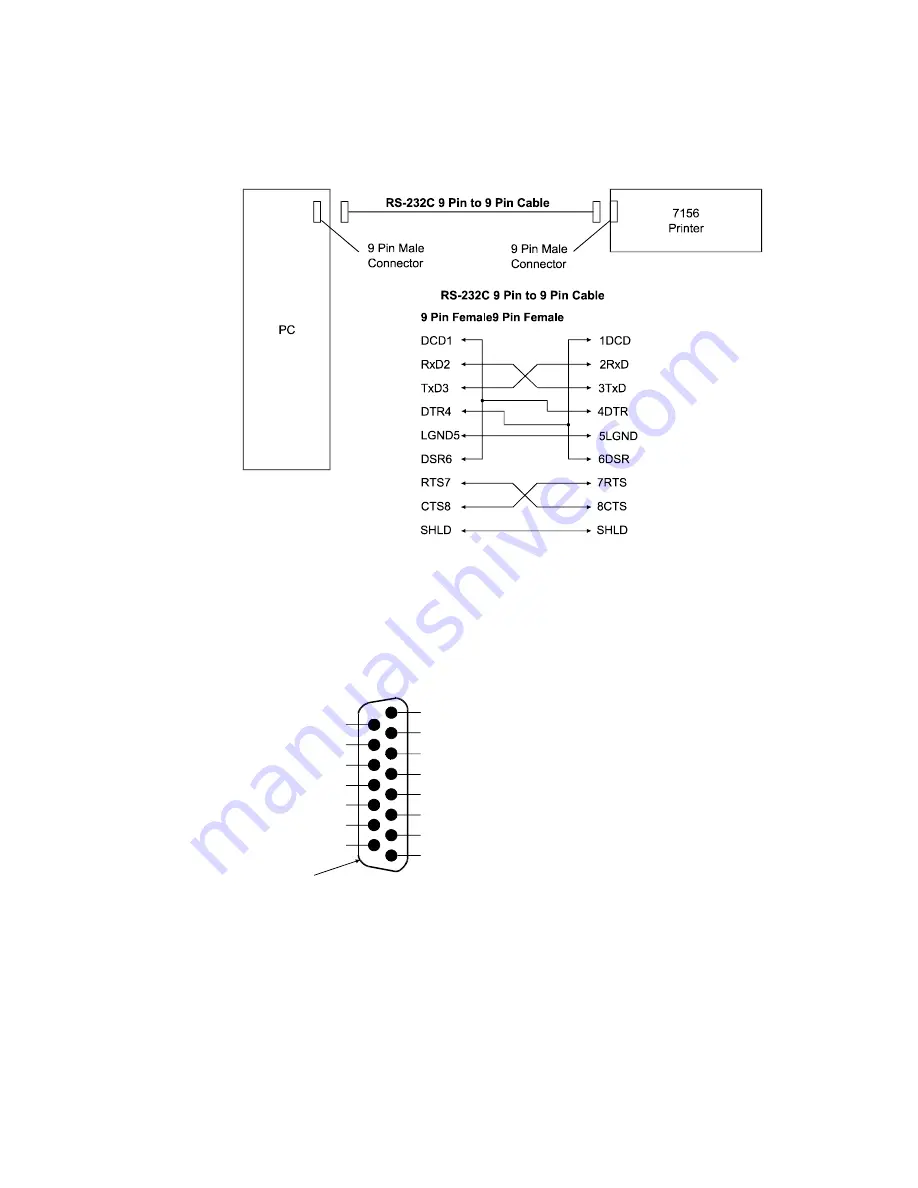

RS-232C 9-Pin to 9-Pin Cable Diagram

Note:

This information is provided for testing and troubleshooting only.

LCSIO (RS-485) Connector and Pin Assignments

24 Volts

Power Ground

Power Ground

5 Volts

Ground

Data B

Not Used

9

10

11

12

13

14

15

Shell-Frame

Ground

1

2

3

4

5

6

7

8

24 Volts

24 Volts

Power Ground

5 Volts

Ground

Data A

Ground

Ground

Function

Function

Pin Numbers

Summary of Contents for 7156

Page 16: ......

Page 20: ...Chapter 1 About the 7156 Printer 7156 Service Guide September 1998 6...

Page 34: ...Chapter 2 Setting Up the Printer 7156 Service Guide September 1998 20...

Page 72: ...Chapter 5 Adjustments 7156 Service Guide September 1998 58...

Page 79: ...7156 Service Guide Chapter 6 Removing the Thermal Receipt Mechanism September 1998 65...

Page 81: ...7156 Service Guide Chapter 6 Removing the Thermal Receipt Mechanism September 1998 67...

Page 99: ...7156 Service Guide Chapter 8 Replacing the Thermal Receipt Mechanism September 1998 85...

Page 101: ...7156 Service Guide Chapter 8 Replacing the Thermal Receipt Mechanism September 1998 87...

Page 108: ......

Page 154: ......

Page 158: ...Chapter 15 Removing the Base Feed Mechanism 7156 Service Guide September 1998 144...

Page 164: ...Chapter 16 Forms Compensation Arm Assembly 7156 Service Guide September 1998 150...

Page 172: ...Chapter 18 Solenoid and Pivot Arm Assemblies 7156 Service Guide September 1998 158...

Page 178: ......

Page 198: ...Appendix D Ordering Paper and Supplies 7156 Service Guide September 1998 184...

Page 204: ...Index 7156 Service Guide September 1998 190...

Page 205: ......