35

1-Step buttonhole stitch

Buttonholes can be adapted to the size of the button.

For stretch fabric or thin fabric, it is recommended to use a stabilizer for a better

buttonhole sewing. Slightly reduce upper thread tension to produce better results.

5~7

Using

the buttonhole foot.

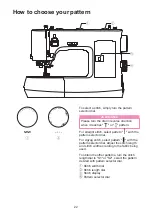

Note

Please use the same fabric of the project

and do a sewing test in advance.

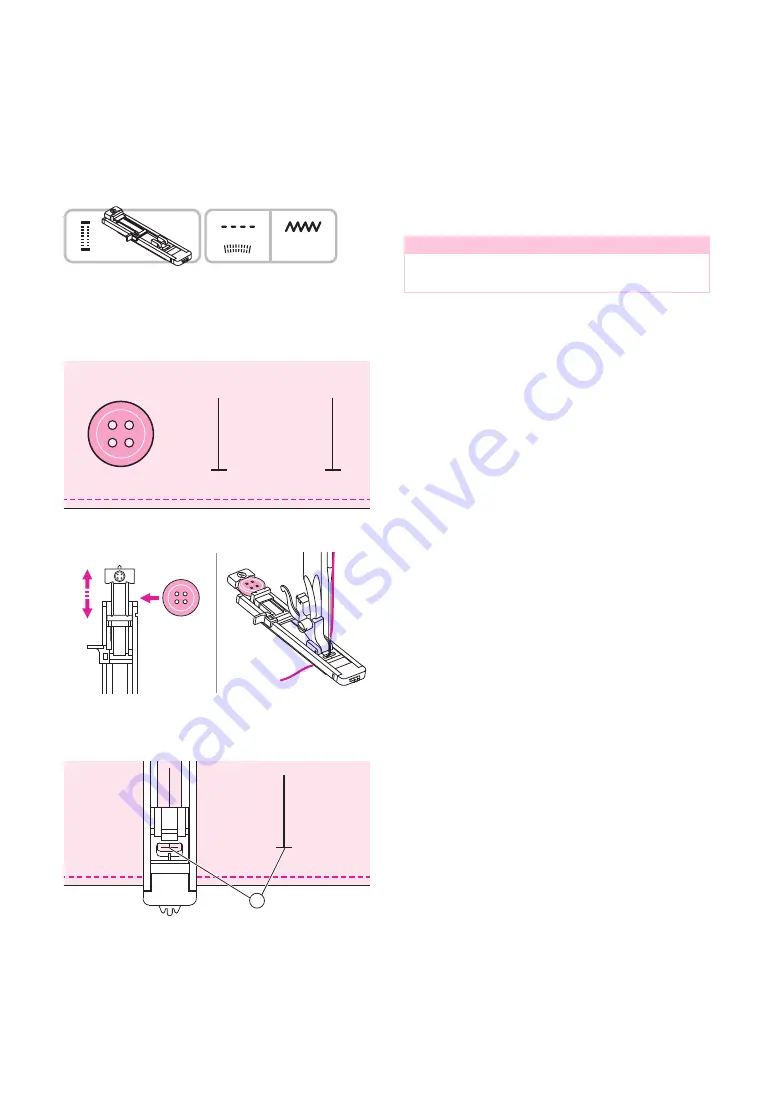

Mark the positions of the buttonhole on the

fabric.

The maximum buttonhole length is 3cm. (Total

of di thickness of button.)

The size of the buttonhole is determined by

the button inserted in the button plate.

Pull the button holder plate to the back, and

place the button in it. Push back the button

holder plate against the button to hold it tight.

Attach the buttonhole foot.

The thread should be passed through the hole

in the presser foot, then be placed under the

foot.

Position the fabric under the presser foot so

that the centerline’s mark is aligning with the

center of the buttonhole foot.

①

Starting point

Select the buttonhole stitch. Adjust the stitch

width and the stitch length to the desired width

and density.

1

Summary of Contents for NC-59QD

Page 1: ...Instruction Manual NC 59QD NecchiAIO Enjoy your Necchi time...

Page 2: ......

Page 7: ...Machine Introduction...

Page 11: ...Machine Setup...

Page 26: ...Sewing Basics...

Page 36: ...Utility Stitches...

Page 56: ...Maintenance and Trouble shooting...

Page 61: ......

Page 62: ......

Page 63: ......