NECTA SPA TECHNICAL MANUAL “COLIBRÌ”

Service Manual: Colibrì

Edition 02-2002

6 /25

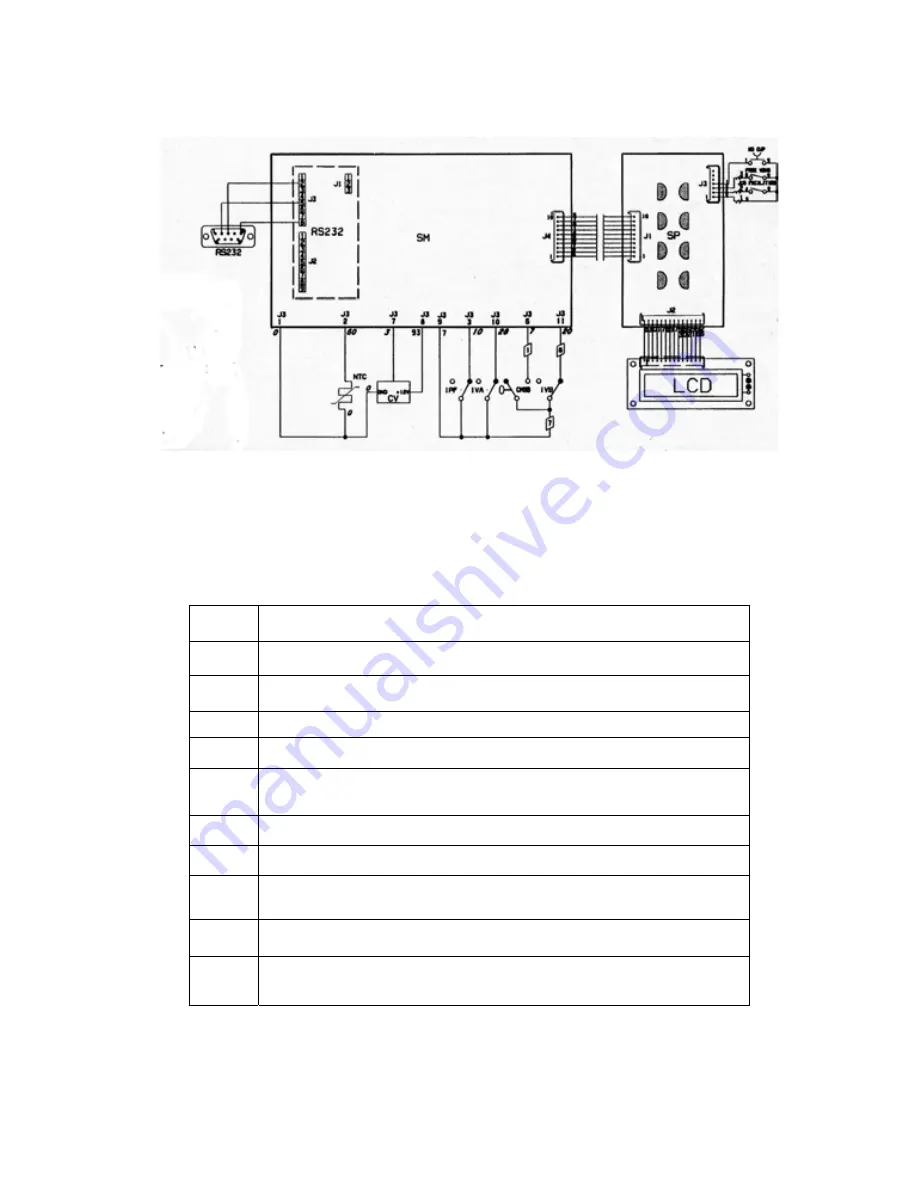

BOARD CONNECTION DIAGRAM

NOTE:

The RS232 serial board for communication protocols can be supplied on request. SERIAL payment systems can

be connected to such board, using the following protocols: Executive - MDB - BDV

As standard feature the vending machine is factory fitted exclusively for the parallel communication payment

systems (12 V front validators)

Code Description

SM

Actuation and control board

LCD

LCD display card

NTC

Temperature control probe

CV

Volumetric counter

RS 232

Printer or data reading device port (only if the relevant optional board is

installed)

SP

Push-button board

IVB

Cup sensor switch

IVA

Water sensor (level) switch (air-break)

IPF

Liquid waste overflow switch (previsions for a model with a support cabinet)

CMSB

Cup release motor cam