NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

6 /

19

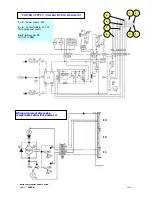

2 - ELECTRICAL SYSTEMS - CONNECTIONS - CONFIGURATIONS

The machine is designed to operate under a single-phase voltage of

230 V AC (+5-10V)

It is protected with

two

T 6,3 A

fuses on both phases.

A safety transformer supplies power to very-low voltage components

(24 V DC),

while the cooling unit and

the Flourescent lamp are powered with the mains voltage.

With regard to the safety transformer:

The primary winding is protected with a

T 800 mA fuse

The secondary winding 25 V is protected with the following fuses::

T 1 A – T 4 A

The slide-out compartment door is fitted with a bipolar safety switch.

The switch is located on the front panel of the power supply unit, and when opening the compartment it

disconnects the power from all parts that can be accessed for normal maintenance and cleaning operations.

The only parts that stay energised are those protected by suitable covers carrying a plate with the warning

"

Disconnect power before removing the cover

”; to clear the voltage the power the power supply cable

must be disconnected from power outlet

or in the case of connection to a dedicated power board, it should

be set to

OFF

The power cable can be supplied as standard feature and chosen

among the following types:

HO5 RN – F copper with a 3 x 1.5 mm

2

section

1)

HO5 VV – F ,, ,, ,, ,,

2)

HO7 RN – F ,, ,, ,, ,,

In all configurations the cable is fitted with a

SCHUKO

plug

permanently fixed to the cable

NOTE :

In the event of replacement cables of exactly the same

characteristics must be used.

Since the “SFERA” vending machine is approved by an

electrical safety certification institute (IMQ), replacements

with non-original components are not permitted.

Otherwise the electrical safety certificate and the warranty will

be void.

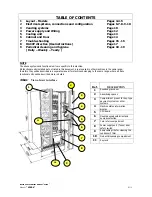

ACTUATION BOARD AND CONNECTIONS

(Electrical compartment open)

A flourescente lamp is located vertically on the right-

hand side inside the cabinet; the starter is fitted

inside the lamp holder. (see page 12)

The ballast is located inside the power supply

compartment.

The CPU board controls also the 24 V actuations by

means of TRIACs and Darlington switches, while the

lamp and the cooling unit are controlled by a relay

card located inside the power supply compartment.

(see page 12)

Some versions are provided with monitoring of the

selected product fall into the dispensing

compartment by means of a card with

receiver/transmitter diodes (infrared).

If during a selection the barrier is not interrupted it

means that a product is finished or jammed, in this

case the system will further attempt releasing the

product with small rotations; if also this fails the

selection is disabled and the customer is entitled to a

new selection.

CPU board and connections

Fluorescent lamp compartment

Protection

fuses

bipolar safety

switch