26

© by NECTA VENDING SOLUTIONS SpA

0110 171-01

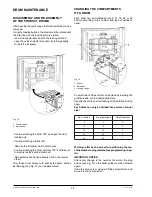

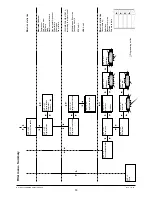

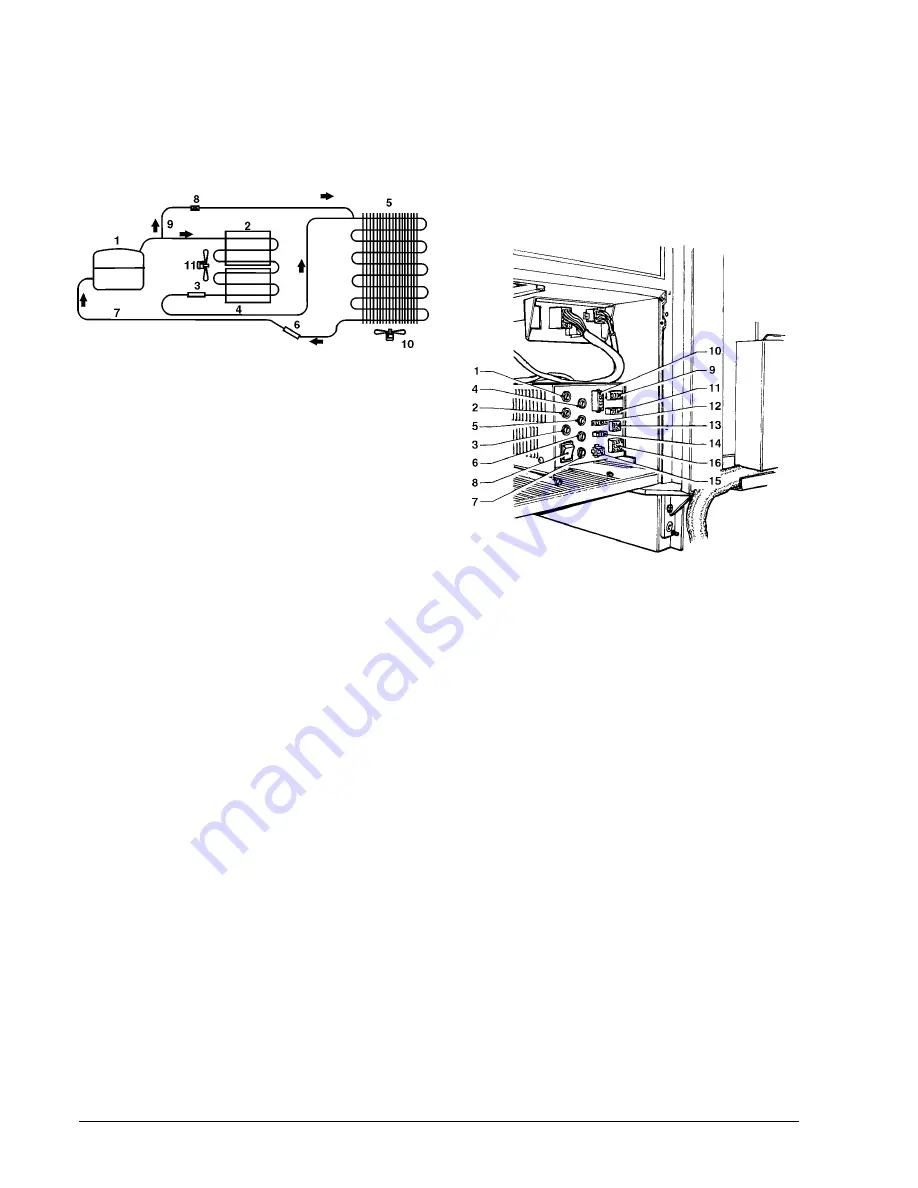

Fig. 19

1 - Compressor

2 - Condenser

3 - Dehumidifying filter

4 - Capillary pipe

5 - Evaporator

6 - Liquids trap

7 - Suction pipe

8 - Bypass valve

9 - Hot gas pipe

10 - Evaporator fans

11 - Condenser fan

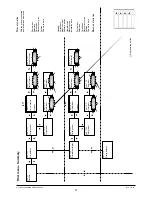

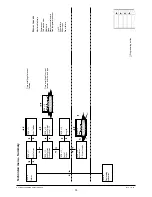

Fig. 20

1

Transformer primary winding fuse

2

Executive coin mechanism fuse

3

24 V DC fuse

4

Heating element fuse

5

Drum magnet fuse

6

Line fuse

7

Line fuse

8

Main switch

9

Power supply to drum magnets and heating elements

10

Connection to stack motor

11

Connection to door lamp

12

Connection to cabinet lamp

13

Power supply to coin mechanism and CPU board

14

Connection to sensors

15

Connection to cold unit

16

Connection to control board

The hot gas produced by the compressor flows directly to

the evaporator through the bypass pipe.

With the bypass solenoid valve open the evaporator fans

are stopped, to avoid a temperature increase inside the

refrigerated box.

MAINTENANCE AND CLEANING

The machine must be kept clean at all times, both inside

and outside.

Normally available products, as long as they are mild, may

be used for cleaning.

When cleaning the drum halves in a dish washer, the

water temperature should never exceed 60° C.

Any detergent residue can cause unpleasant odour

inside the machine!

To ensure perfect operation, the product slider guides

should always be kept clean.

Never use grease or oil!

IMPORTANT NOTICE

The drums must never come into contact with grease or

oil!

The condenser must be kept clean using a vacuum

cleaner, a brush etc.

POWER SUPPLY UNIT

The fuses, switches and connectors which are on the front

of the power supply unit have the functions indicated

below.

When the protective casing is fitted, only the fuses and the

main switch are accessible.

When replacing any fuses the machine must be discon-

nected from the power supply.

Summary of Contents for StarFood

Page 2: ......

Page 4: ......

Page 56: ...NECTA VENDING SOLUTIONS SpA...

Page 57: ...Star ood...

Page 58: ...NECTA VENDING SOLUTIONS SpA...

Page 59: ...Star ood...

Page 60: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Page 61: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Page 62: ...by NECTA VENDING SOLUTIONS SpA NOTE...

Page 64: ......