Vacuum Hose Reel 881 EX

NOTE!

When replacing the spring the spring power

must be completely neutralized (instruction is

delivered together with the spare part spring).

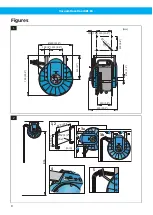

5.1.2 Mounting/Replacing the hose

See

.

When the reel has been mounted on a wall or ceiling,

the hose is replaced in the following way:

NOTE!

• Ensure that the drum is locked by the safety

• Use only Nederman hoses.

1

Remove the cover plate.

2

Remove the old existing hose.

3

Fit the existing hose coupling to the new hose end

and fit the new hose on the connecting piece in-

side the drum.

NOTE!

For the length of hose from swivel to

clamp, see

4

Fasten the new hose with the hose clip on the

drum according to the picture.

5

Fit the cover plate.

6

Unlock the safety lock.

7

Let the hose recoil by turning the drum by hand.

Make sure that the hose forms evenly divided on

the drum.

8

Fit the hose stop in the desired position, see

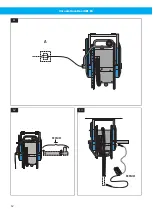

5.1.3 Ratchet mechanism

See

.

The hose reel is delivered with a ratchet mechanism

which retains the hose in the required out-drawn po-

sition. The ratchet will disengage if the hose is drawn

out a little further, and the hose then recoils to the

drum.

NOTE!

The hose should be held by hand as long as

possible during the recoiling.

The ratchet is factory set for wall mounting of the

reel, see

/A. When mounting the reel in the

ceiling, the ratchet must be moved from one position

to another, see

NOTE!

The ratchet must, after it has been mounted,

point towards the centre of the reel, see

.

If the hose is pulled out too far, the ratchet could, un-

fortunately, become permanently locked. It may be

released by the following procedure.

1

Take a steady grip on the drum end plate and turn

a little in the outdraw direction until the ratchet is

disconnected.

2

Holding the endplate and hose at the same time,

slowly release until the hose has recoiled.

3

Fit the ratchet in the other mounting position.

5.1.4 Adjustment of spring tension

.

The reel has a factory set basic spring tension which

after mounting the reel could need an adjustment.

NOTE!

Do not tense the spring more than is needed to

exactly roll the hose to its rest position.

Increasing the spring tension

1

Make sure that the hose is in place and fully re-

coiled on the reel.

2

Use the socket head cap spanner which comes

with the reel. Turn in the direction of the arrow as

shown in the picture.

3

Tense the spring one revolution at a time and test

the coiling operation gradually.

NOTE!

Check that the hose can be fully uncoiled

without stretching the spring to its maxim-

um. If not, decrease the spring tension.

Decreasing the spring tension

1

Make sure that the hose is in place and fully re-

coiled on the reel.

2

/A.

3

Remove the hose stop.

4

Remove one coil of hose.

5

Refit the hose stop.

6

/A.

5.1.5 Damper function

The reel is fitted with a mechanical damper which

automatically opens when the hose is pulled out. The

damper closes when the hose is rewound. Always

check that there is enough suction in the hose before

use. If not, pull the hose out, corresponding approxim-

ately one revolution, to open the damper.

5.2 Installation in non-ATEX zone

and

5.2.1 Connection to duct

.

The hose reel should be connected to the fixed duct

and high vacuum extraction system with a connection

hose, see

/A.

EN

19

Summary of Contents for 30805881

Page 9: ...Vacuum Hose Reel 881 EX 3a Ø38 mm L 160 170 mm Ø50 mm L 220 230 mm 3b 1 7 Nm 3c 9 ...

Page 10: ...Vacuum Hose Reel 881 EX 4 A B C 5 6 A 7 10 ...

Page 11: ...Vacuum Hose Reel 881 EX A 8 9 A B 10 11 ...

Page 12: ...Vacuum Hose Reel 881 EX A 11 R 1MΩ 12 R 1MΩ 13 12 ...

Page 14: ...Vacuum Hose Reel 881 EX 38 mm m3 h kPa 16 50 mm kPa m3 h 17 14 ...

Page 120: ...www nederman com ...