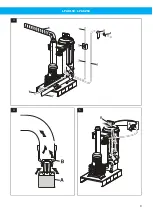

L-PAK 150, L-PAK 250

NOTE!

The exhaust air duct should be routed straight

and as short as possible. Pressure drop for com-

plete system shall be considered by the install-

ation designer or the user.

1

Incoming 3-phase power supply with PE cable.

2

Switch-disconnector according to standard.

3

Power cable to the unit.

4

Compressed air valve, size G1/4” or G1/2”.

5

Water and dirt-trap. Compressed air supply must

be clean and dry.

6

Compressed air supply, Ø 6 mm nylon hose.

7

Vacuum pipe from workstations.

8

Exhaust air duct Ø 100 mm. Ø 160 mm pipe is used

for lengths greater than 12 m.

9

Pilot signal cable (PS) from valves at workstations.

(AS-set required, accessory.) Strap terminals

13-14 when the pilot signal cable is not installed.

5 Initial Start-up

WARNING! Risk of personal injury

Never run the unit without an exhaust air duct.

An incorrectly installed/positioned exhaust air

duct can cause personal injury. The exhaust

air/exhaust air duct can reach high temperat-

ures.

The L-PAK 150, L-PAK 250 with options is tested be-

fore delivery and all functions are checked.

5.1 Before starting for the first time

Before starting for the first time, check that:

• The switch-disconnector is installed.

• The unit room, if small, has ventilation openings.

See

• The plastic sack is in place in the collector bin. The

unit should not be used without a plastic sack!

• The pipework is connected to the dust collector in-

let.

• An exhaust air duct is attached to the outlet to lead

away hot exhaust air.

• The compressed air supply is permanently connec-

ted. Filter cleaning, idling and cooling do not func-

tion when there is no compressed air!

• Pilot signal cable installed (when the function auto-

matic start/stop is used).

• The terminals 13-14 in the start and control unit are

strapped when the system is not equipped with the

automatic start/stop function i.e. the pilot signal

cable is not routed to workstations.

5.2 Start-up

The expression “automatic start/stop” in the following

text means both automatic idling and automatic start/

stop.

NOTE!

The acoustic enclosure (accessory) should be

removed during initial start-up to check the dir-

ection of rotation. Check that there are no open

vacuum valves at the workplaces.

• See

. Turn the switch-disconnector to posi-

tion 1.

• See

. Press the white push button on the

control panel until the white lamp lights. When the

automatic start/stop function is not used the unit

should start directly.

NOTE!

When the L-PAK 150, L-PAK 250 has the auto-

matic start/stop function enabled it should not

start directly except when a valve at a worksta-

tion is opened or when the button for Manual

start is pressed, see

• Check the direction of rotation with the arrow mark.

If these correspond then allow the starting proced-

ure to continue. Otherwise, stop the unit by press-

ing the button shown in

. Isolate the power

by using the switch-disconnector. Open the start

and control unit and change two of the incoming

phase conductors. Check the rotation again.

• Check that the unit, if it has automatic starting and

stopping, does not start immediately when the but-

ton marked in

is pressed. The lamp in the

push button should come on to indicate that the

starter is now in “Standby” mode and ready to re-

ceive the start signal from the pilot signal cable.

The unit should not start until you open a valve at

a workplace so that the microswitch makes, or you

press Manual start.

After approximately 30 seconds the unit switches to

idling (and filter cleaning). After 10 minutes the unit

should stop. If the unit starts without any valve being

opened this is an indication that the pilot signal cable

is closed at some point. Disconnect the cable from the

starter and use an ohmmeter across the leads in turn

until the fault has been located and remedied.

• Press the Manual Filter Cleaning button shown in

, and check whether the filter cleaning pro-

cedure starts. The valve is hidden under the en-

closure, but a distinct change in sound reveals the

function, this will be repeated 3 times for each filter

cleaning cycle.

• With the pipework fully sealed and all valves at

workstations closed, verify that the vacuum limiting

valve opens and admits air to limit the vacuum.

• Replace the cover on the start and control unit

when all controls have been carried out. Replace the

EN

21

Summary of Contents for 40051800

Page 8: ...L PAK 150 L PAK 250 Figures 1 2 8 ...

Page 9: ...L PAK 150 L PAK 250 3 4 5 9 ...

Page 10: ...L PAK 150 L PAK 250 6 7 8 9 10 10 ...

Page 11: ...L PAK 150 L PAK 250 11 12 13 14 11 ...

Page 178: ...www nederman com ...