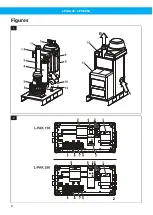

L-PAK 150, L-PAK 250

EN

acoustic enclosure over the motor/fan and the top

cover over the dust extractor.

• Switch off the unit at the end of the shift by press-

ing the white push button shown in

on the

control panel (even when the unit has automatic

start/stop) and turning the switch-disconnector to

0.

6 Maintenance

Read

be-

fore carrying out any maintenance work.

Maintenance work means that the equipment will

have to be opened and possibly dismantled. This may

constitute a risk and the maintenance personnel need

to know about the risks that may occur when acting

incorrectly.

Always replace damaged, worn or defective electrical

components or other parts with new original parts.

WARNING! Risk of personal injury

An approved protective mask should be used

when emptying the collector bin and when

replacing filters in the dust collector and mi-

cro-filter.

6.1 Checks one month after installation

and every year

One month after installation, and then every year,

perform the following checks:

• Check all power and protective conductors and

ground wire connections. Tighten, if required, to en-

sure good contact.

• Inspect valves, hoses and seals for leakage.

• Clean the area around the unit and all areas where

the collected material is stored to ensure that there

are no dust deposits.

• Check that all signs/markings regarding safe opera-

tion are in place and that the personnel knows about

them.

• Verify the function of all emergency stop buttons,

alarms and signalling devices.

6.2 Collector bin

WARNING! Risk of personal injury

Always use an approved breathing mask when

replacing the dust sack.

Empty the collector bin regularly and before it be-

comes 2/3 full, see

. If the bin is too full it in-

creases the load on the filters. Replace the plastic sack

with a new one (no holes) and re-connect the connec-

tion hose, see

.

NOTE!

Check that the connection hose is intact and

not blocked.

The plastic sack is held in position in the bin by feeding

negative pressure to the outside of the sack via the

hose that runs from the bottom of the bin to the dust

collector.

6.3 Changing the filter

WARNING! Risk of personal injury

Always use an approved breathing mask when

changing the filter.

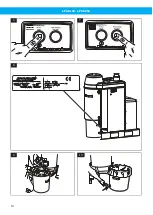

6.3.1 Filter package

The following filter packages are available for L-PAK

150, L-PAK 250, see

position A - D:

(A) Filter package, PP. Replacing the entire filter pack-

age is recommended. When only changing the socks,

the filter ring should also be replaced.

(B) Filter package, cartridge

(C) Filter package, CF

(D) Filter package, sack

Change the whole filter package after about 5,000

hours of operation or a maximum of 3 years. If welding

fumes are filtered these figures should be reduced to

3000 hours and 2 years.

NOTE!

The changing interval of the filter is dependant

of the material the unit handle. If uncertainties

arise of changing intervals, contact the distrib-

utor or Nederman.

1

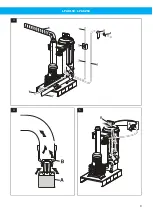

Remove the top cover and the dust extractor’s

cover.

2

shows how the filter package with filter

socks are removed.

3

Place the old filter package in a large plastic sack,

see

, or wrap in plastic foil. Avoid dust

spreading.

6.3.2 Micro-filter (accessory)

Replace the micro-filter, see

, every 12

months or more frequently if the suction capacity de-

preciates. For placement see

position 4. Care-

fully lift out the filter, place it in a plastic sack and seal

the bag with care.

6.4 Filter cleaning

1

Check the automatic cleaning equipment.

2

Remove the top cover from the collector and in-

spect the valve disc.

3

Startup the unit and press the Manual Filter Clean-

ing button, see

The compressed air cylinder should lift the valve disc

and loud noise can be heard as air rushes into the col-

lector to blow off the dust from the outside of the fil-

ter package.

22

Summary of Contents for 40051800

Page 8: ...L PAK 150 L PAK 250 Figures 1 2 8 ...

Page 9: ...L PAK 150 L PAK 250 3 4 5 9 ...

Page 10: ...L PAK 150 L PAK 250 6 7 8 9 10 10 ...

Page 11: ...L PAK 150 L PAK 250 11 12 13 14 11 ...

Page 178: ...www nederman com ...