L-PAK 150, L-PAK 250

NOTE!

If the vacuum cleaner comes with a control sys-

tem for timer controlled cleaning, see it’s set-

tings instructions for information regarding its

use.

6.5 Motor and the fan unit

The motor has two ball bearings. The bearings should

be replaced after approximately 20,000 of operation.

If ambient temperature often reaches 40 °C (104 °F)

this figure should be reduced to 15,000 hours. In any

case, the bearings should be changed every fifth year.

The bearings are a standard type and can be fitted

by any firm equipped to rewind electrical motors. Old

grease should be removed and new grease used. The

grease must be up to the DIN 51825- K3N standard.

Suitable brands are Shell Grease 16, Esso Unirex N3

and Statoil Uniway UTC 3.

NOTE!

• Check all power conductor connections and

ground wires regularly. Retighten if required

to ensure good contact.

• Check regularly that the exhaust air duct is

not defective, all the way from the fan to the

duct’s outlet. Remember that the exhaust air

duct can be hot.

6.6 Running meter

The unit is equipped with a running meter that indic-

ates when a service/maintenance should be carried

out.

This is indicated by the white lamp on the control pan-

el flashing slowly. When indicated, service/ mainten-

ance must be carried out at the earliest possible date.

The time between service is 2000 hours.

7 Spare Parts

CAUTION! Risk of equipment damage

Use only N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

original spare parts and ac-

cessories.

Contact your nearest authorized distributor or

N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

for advice on technical service or

if you require help with spare parts. See also

w

$

w

$

w

$

.

$

n

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

.

$

c

$

o

$

m

$

.

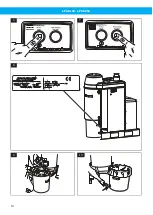

7.1 Ordering spare parts

When ordering spare parts always state the following:

• The part number and control number (see the

product identification plate).

• Detail number and name of the spare part (see

w

$

w

$

w

$

.

$

n

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

.

$

c

$

o

$

m

$

/

$

e

$

n

$

/

$

s

$

e

$

r

$

v

$

i

$

c

$

e

$

/

$

s

$

p

$

a

$

r

$

e

$

-

$

p

$

a

$

r

$

t

$

-

$

s

$

e

$

a

$

r

$

c

$

h

$

).

• Quantity of the parts required.

8 Recycling

The product has been designed for component mater-

ials to be recycled. Different material types must be

handled according to relevant local regulations. Con-

tact the distributor or

$

N

$

e

$

d

$

e

$

r

$

m

$

a

$

n

$

if uncertainties arise

when scrapping the product at the end of its service

life.

EN

23

Summary of Contents for 40051800

Page 8: ...L PAK 150 L PAK 250 Figures 1 2 8 ...

Page 9: ...L PAK 150 L PAK 250 3 4 5 9 ...

Page 10: ...L PAK 150 L PAK 250 6 7 8 9 10 10 ...

Page 11: ...L PAK 150 L PAK 250 11 12 13 14 11 ...

Page 178: ...www nederman com ...