Trouble Shooting

Problem

Fault

Solution

Motor will not start

Electrical supply not connected

Connect the electrical supply.

Thermoswitch not reset or defect (T-mod)

Dismantle top cover and clean or exchange

cooling air filter. Reset the thermoswitch. If the

thermoswitch is defect, please contact the

distributor.

Switch supply or cable defect

Contact the distributor

Radio interference suppression defect

Contact the distributor

None or bad suction capacity

Switch not completely turned on

Turn switch on

One or two motors defect

Dismantle top cover, control the brushes and

commutators. If the brushes are worn out, please

replace. If the commutators are burnt, contact the

distributor.

Clogged suction hose or inlet

Disconnect suction hose. Turn and suck in the

opposite direction. If still clogged, open it with a

rod.

Clogged filter

For filter bag and cartridge filter cleaning; please

see operation instruction.

NCF filter cleaning; check filter cleaning

function by listening to noise from blow-out

valve. If not in operation, check quick coupling

and function of blow-out valve.

Leaking suction hose

Tape or replace suction hose.

Leaking gaskets

Damage on neoprene gasket; remove and

replace. Use suitable two-component glue.

Discharge valve open.

Close valve

Dust in exhaust air

Filter wrongly or not installed

Check the filter and change if necessary.

Filter defect

Change filter.

Water in exhaust air

Filter basket or float ball wrongly or not

installed

Reattach filter basket or float ball.

Please see operation instruction.

Filter basket or float ball defect

Change.

Abnormal noise level

Leaking gaskets

Damage on neoprene gasket; remove and

replace. Use suitable two-component glue.

Sound absorbing material defect

Dismantle the silencer hood and remove dirt.

Replace damaged silencing material.

Summary of Contents for 42122106

Page 17: ...MAX 8 bar 43214001 43214100 S235JR St37 2 Ex Z Y ìí ð îê ððï ...

Page 23: ...43907004 43907013 43907104 43907015 S235JR St37 2 ì ì ìí é îí ððï ...

Page 24: ...11 02 2010 Material C F PE PVC PUR ìí è ïî ïðð ì ...

Page 26: ...18 06 2008 Addendum to Manual ...

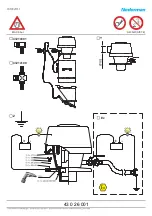

Page 28: ...6 8 bar OK 1 2 3 1 2 3 ...

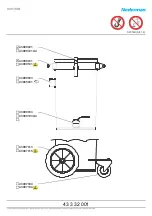

Page 29: ...1 4 2 5 3 6 7 3mm 1 2 3 4 5 10mm 1 4 Ø 2 5 L 500mm ...

Page 31: ......

Page 32: ...www nederman com ...