SERVICE FORM

6.0

OTHER ITEMS (CONT.)

6.3

6.4

6.5

6.6

6.7

6.8

6.9

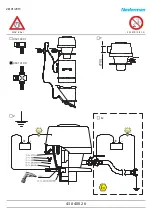

WARNING! Risk of personal injury.

Completely disconnect the vacuum cleaner from all power sources before any type of service.

1.2

Control the cable and plug, and replace it is if damaged.

1.5

Replace leaking suction hoses and couplings.

2.1

Replace worn out, aged and leaking gaskets.

2.4

Repair or replace worn out filters to avoid wear and tear of the turbine rotor or blow through of health

hazardous materials.

2.5

Replace torn or full antistatic dust bag.

Repair or replace reusable dust bag. If it is clogged, wash or shake it clean.

2.6

Clean the water level limiting device regularly and examine it for signs of damage.

3.1

Start the motors in sequence using the main switch. If the main switch does not function properly or is

damaged, replace it.

3.2

If specified vacuum is not reached, check all gaskets and connections. Execute the vacuum test with

suction inlet(s) closed.

3.3

If the noise level is higher than the maximum specified, dismantle the silencer hood and check the

silencing material. Replace it if it is damaged.

WARNING! Risk of personal injury.

Do not touch the motor with any tool during the following operation ‘4.1’ below.

4.1

Start the vacuum with the top cover removed.

Control that the motors are running clockwise as seen from above.

4.2

Control the thermal function by clogging the cooling air inlets with sheets of paper. The vacuum should

soon stop without getting overheated (about 75˚C/167 ˚F).

5.1

Control that all cable connections are properly secured and screws tightened.

5.2

Control that the carbon brushs are not worn out. Replace them if necessary.

Replace after about 900 hours. Replaced brushes must be checked after 500 hours.

5.3

Control wear of commutator. Replace motor if commutator is grooved.

5.4

Turn on motor. If there is resistance in bearings or turbo fan, replace the motor.

5.5

If any wiring in the printing card is burned, replace the card.

Summary of Contents for 42172207

Page 14: ...722A NE76 S200 42172207 43627003 ...

Page 16: ...MAX 8 bar 43214001 43214100 S 235JR S t37 2 Ex Z Y 28 01 2013 43 0 400 26 ...

Page 24: ...18 06 2008 Addendum to Manual ...

Page 26: ...6 8 bar OK 1 2 3 1 2 3 ...

Page 27: ...1 4 2 5 3 6 7 3mm 1 2 3 4 5 10mm 1 4 Ø 2 5 L 500mm ...

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ...www nederman com ...