Hose Reel 876

EN

1 Preface

Thank you for using a Nederman product!

The Nederman Group is a world-leading supplier and

developer of products and solutions for the environ-

mental technology sector. Our innovative products

will filter, clean and recycle in the most demanding of

environments. Nederman's products and solutions will

help you improve your productivity, reduce costs and

also reduce the impact on the environment from in-

dustrial processes.

Read all product documentation and the product iden-

tification plate carefully before installation, use, and

service of this product. Replace documentation imme-

diately if lost. Nederman reserves the right, without

previous notice, to modify and improve its products

including documentation.

This product is designed to meet the requirements

of relevant EC directives. To maintain this status, all

installation, maintenance, and repair is to be done

by qualified personnel using only Nederman original

spare parts and accessories. Contact the nearest au-

thorized distributor or Nederman for advice on tech-

nical service and obtaining spare parts. If there are

any damaged or missing parts when the product is de-

livered, notify the carrier and the local Nederman rep-

resentative immediately.

2 Safety

2.1 Classification of important informa-

tion

This document contains important information that

is presented either as a warning, caution or note, ac-

cording to the following examples:

WARNING! Risk of personal injury

Warnings indicate a potential hazard to the

health and safety of personnel, and how that

hazard may be avoided.

CAUTION! Risk of equipment damage

Cautions indicate a potential hazard to the

product but not to personnel, and how that

hazard may be avoided.

NOTE!

Notes contain other information that is import-

ant for personnel.

3 Description

The Hose Reel 876 is designed for transport of gas for

welding purpose.

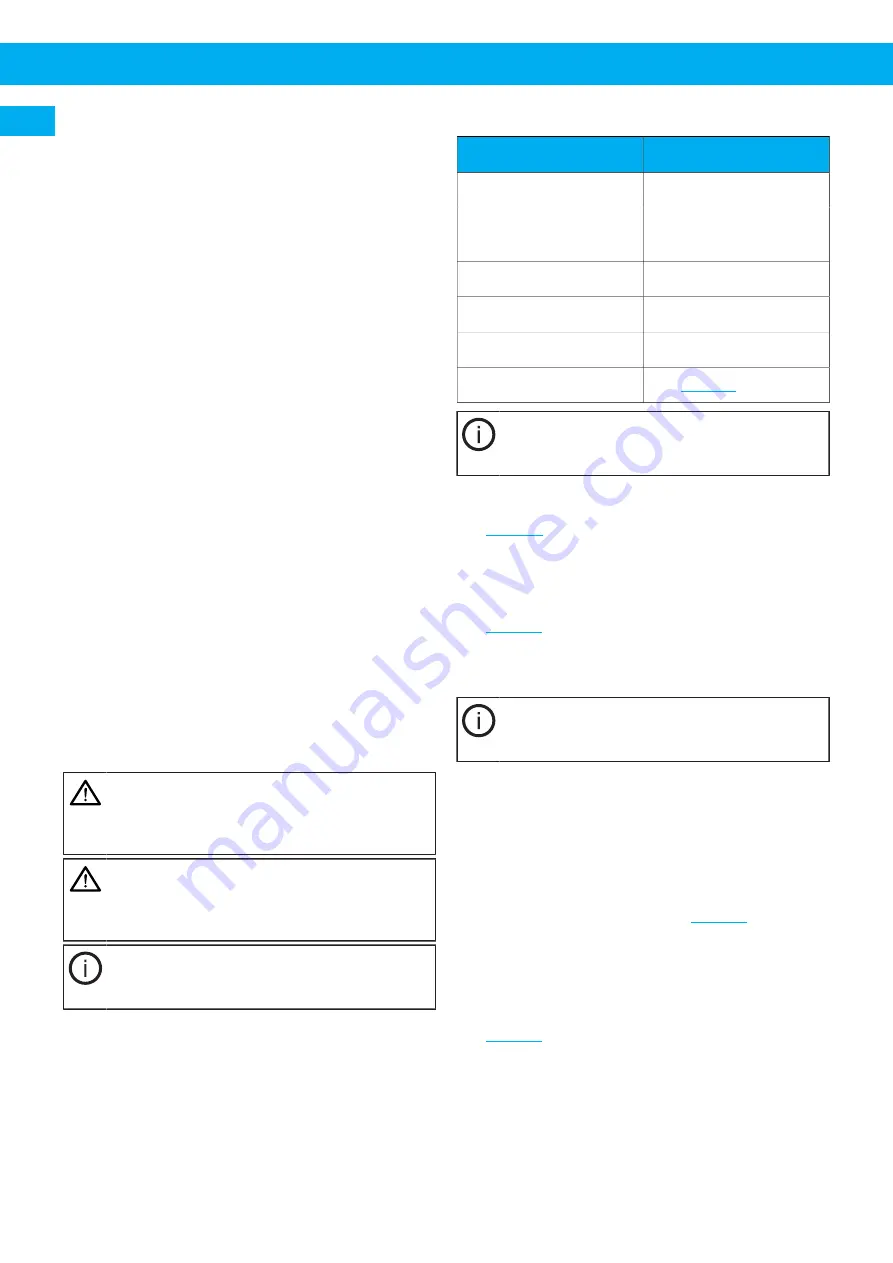

3.1 Technical data

Ser. 876

Weight, incl. hose

26–30 kg

Maximum mounting

height

4.0 m

Max working pressure

2.0 MPa (290 psi)

Ambient temperature

−10 °C – +60 °C

Material recycling

70–72 weight-%

Dimensions

See

.

NOTE!

The hose on Hose Reel 876 must apply to

standard ISO 3821 and EN 1256.

4 Using Hose Reel 876

.

5 Installation

5.1 Mounting instruction

. The Hose Reel 876 is delivered for ceil-

ing mounting (item 1) but can also be used for floor or

wall mounting.

• Use wall bracket (item 2) for wall mounting.

NOTE!

Only in exceptional cases mount as items 3 or

4.

Item 5: The hose must not bend on the hose outlet.

• Select a level surface on which to mount the Hose

Reel 876. Ensure that suitable fixing bolts are used

and that they are secure. The bolts must stand a

torque force of minimum 7400 N.

5.2 Hose outlet

For recommended grounding, see

outlet can be turned and locked in different positions.

• Choose the position where the hose is bent as little

as possible.

5.3 Connection to the pipework system

. The reel must be connected to the pipe-

work system with hose only, minimum 0.5 m.

• Check that the hose is not twisted or strained after

connection. Fix the inlet hose (see item *) so that

it does not rotate when pulling out the distribution

hose.

12