Trolley Return Unit 920/1500

27

EN

9

Troubleshooting

Table 9-1: Troubleshooting table

Cause

Solution

The system does not react to

any activity.

Check that the working switch is switched on and that the power fuse is

intact. Measure the power supply after the working switch. Check that

the fuse F1/ 2 or 4 A time lag T is intact and that the power supply can

be measured after the fuse. Also check the transformer voltage setting

according to Circuit diagram 1.

The fan does not start when the

suction hose is lowered.

Pull the suction trolley from connection position: if the fan still does not

start, search for a short circuit in SLX1 (disconnection arrow). If the fan

starts, search for a short circuit in SLX (limit position on suction trolley).

Check that fuse (F2/ 2AT) is intact. Check that there is 24 VAC power

supply.

The Drive motor does not start.

Check that the fuse F 10 AT is intact. The fuse is located on the control

board in the Drive unit. Check the emergency stop. Contact K1 is off when

the emergency stop is depressed. Measure the voltage on K1 to the drive

motor 15 - 24 VDC.

The Drive motor starts but stops

after 3 seconds.

Check limit switch SL4: release SL4 from the stop ball and measure on

the wires when SL4 is unaccuated. If SL4 is closed when unaccuated,

(SL4 is open when unaccuated and closed when accuated), then search

for a mechanical or electrical fault in the limit switch or a short circuit in

the wires.

The Drive motor does not stop

after passing the limit switch

SL4.

Limit switch SL4 circuit is defective. Open circuit in switch or cabling.

Action: Allow the drive motor to run approximately 120 seconds until it

stops. If the suction trolley is in connection position, pull out the trolley

so that you release the driving slot from the disconnection arrow and

then press the start button. Drive motor starts and will pull the suction

trolley into connection position. After this manoeuvre SLX and SLX1 have

taken over the function of SL4 to stop the drive motor and the system can

continue to run until the fault can be corrected.

Summary of Contents for 920/1500

Page 2: ...Trolley Return Unit 920 1500 2 ...

Page 3: ...Trolley Return Unit 920 1500 3 English 4 ...

Page 28: ...Trolley Return Unit 920 1500 EN 28 Appendix A Cable connections Cable connections overview ...

Page 29: ...Trolley Return Unit 920 1500 29 EN Simple cable connections overview ...

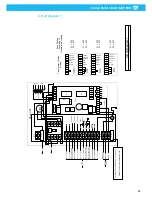

Page 30: ...Trolley Return Unit 920 1500 EN 30 Appendix B Circuit diagrams Driving slot circuit diagram ...

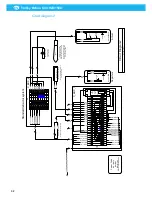

Page 31: ...Trolley Return Unit 920 1500 31 EN Circuit diagram 1 ...

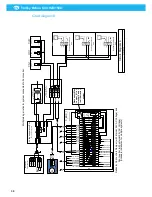

Page 32: ...Trolley Return Unit 920 1500 EN 32 Circuit diagram 2 ...

Page 33: ...Trolley Return Unit 920 1500 33 EN Circuit diagram 3 ...

Page 34: ...Trolley Return Unit 920 1500 EN 34 Circuit diagram 4 ...

Page 35: ...Trolley Return Unit 920 1500 35 EN Circuit diagram 5 ...

Page 36: ...Trolley Return Unit 920 1500 EN 36 Circuit diagram 6 ...

Page 37: ...Trolley Return Unit 920 1500 37 EN Circuit diagram 7 ...

Page 38: ...Trolley Return Unit 920 1500 EN 38 Circuit diagram 8 ...

Page 39: ...Trolley Return Unit 920 1500 39 EN Circuit diagram 9 ...

Page 40: ...Trolley Return Unit 920 1500 EN 40 Circuit diagram 10 ...

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ...www nederman com ...