FilterBox

19

EN

4

Use FilterBox

WARNING!

Risk of fire and explosion.

• Do not use the product for flammable or explosive dust and gases.

•

Do not use the product in an environment where there is a danger of

explosion, or where there is dust or gases in explosive concentrations.

•

If the product has been used for dust applications, do not use it for welding

fumes or grinding dust.

•

Do not use the product for extracting toxic substances (except welding fumes).

• Do not use the product without filter cartridge and casing.

•

Only use the product in a well-ventilated room.

• In case of fire, smoke from the product may contain hazardous substances

such as burning polycarbonate, PVC, polyethylene, etc. Also, depending

on the material being separated, there may be hazardous smoke from the

separated dust.

• In case of fire, disconnect power to the product at the mains. Use a fire

extinguisher, minimum class AB.

WARNING!

Risk of fire.

Check that no sparks or other objects that can cause fire are sucked in to the

arm. For welding applications generating a high amount of sparks, a spark

protection (accessory) must be mounted in the hood to reduce the risk of fire.

WARNING!

Risk of personal injury.

Only properly trained personnel are allowed to use this product.

CAUTION!

Store FilterBox indoors in a dry environment.

NOTE!

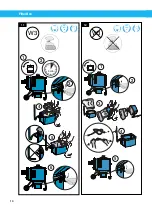

Position the extractor arm hood correctly, see figure 1.

4.1

Start FilterBox

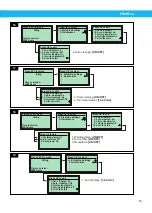

See the control panel in figure 2.

1.

Turn the main power switch L to ON.

2.

Start FilterBox with the button S1, or switch on extractor arm hood.

4.2

Overload protector

FilterBox is equipped with an overload protector that automatically disconnects

the power if the fan motor becomes overloaded. For a list of possible causes,

see the

FilterBox Installation and Service Manual

.

4.2.1

FilterBox M

See figure 2. If the overload protector is activated, FilterBox goes into OFF

mode. To reset the overload protector alarm, correct the problem, and turn the

main switch L back to ON.

4.2.2

FilterBox A / FilterBox eQ

See figure 2, item F. LED F is red and indicates that the fan motor is

overloaded.

The overload protector automatically resets after a few minutes. To manually

reset the overload protector, turn main switch L to OFF and then turn it to ON.