29

YES

NO

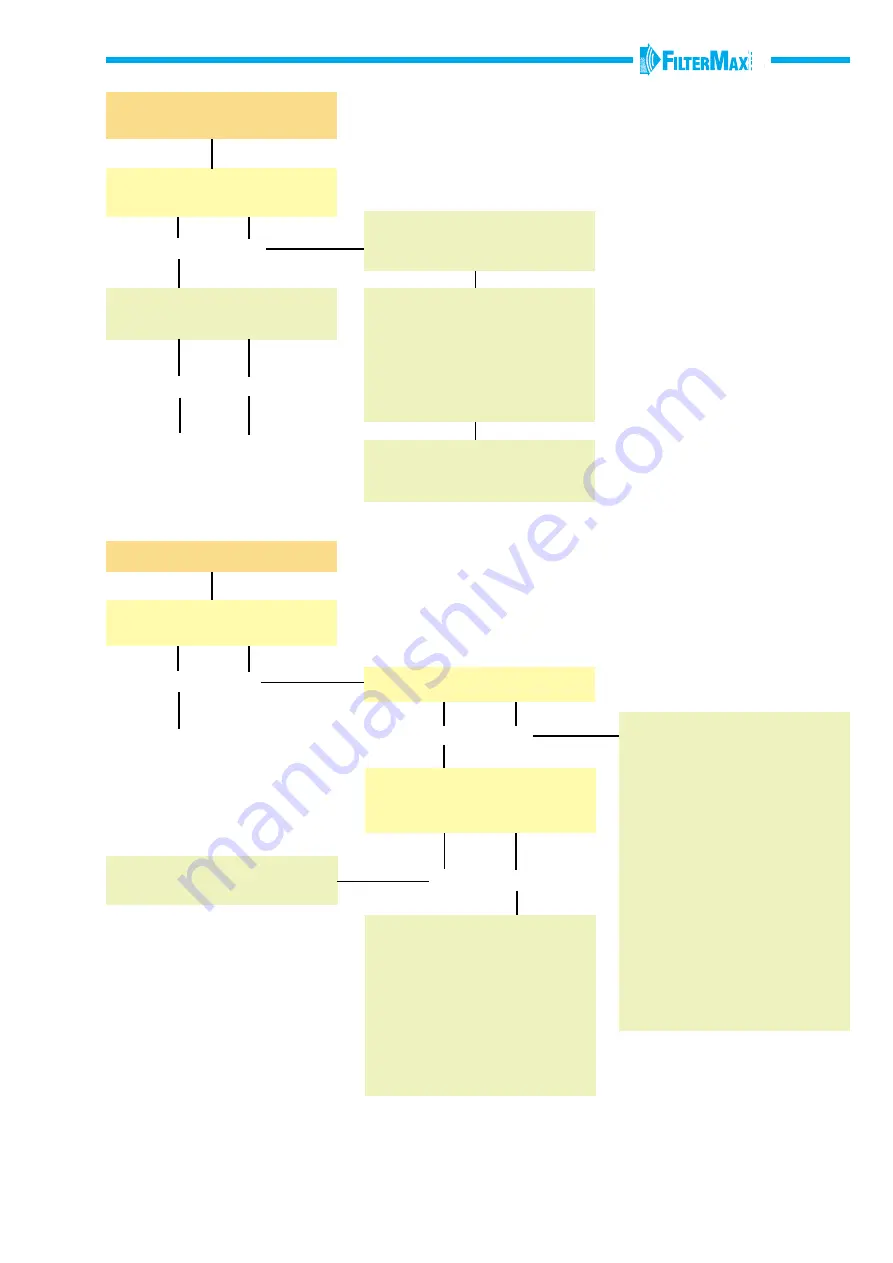

The FilterMax DX pressure

resistance is high.

D

Are there some valves that are

functioning?

Go to

F

Go to

B

NO

YES

Check the pressure of the com-

pressed air. It should be 0,6 MPa

(6 bar, 87 psi).

Is the cleaning system fully

functioning?

Check the pause time set on the

timer (see page 16). The default

value is 30 s. A heavy application

or a 2 - 3 module unit (12 - 18 filter

cartridges) will require shorter

times. A very light application can

use longer times.

If the cleaning has been adjusted

previously you may have to replace

the filter cartridges.

NO

YES

Check if the system contains any

dampers and the position of these.

Open dampers to adjust the flow,

but don’t exceed the dimensioned

airflow for the filter unit.

Check that the filter unit’s inspection

panels are closed.

Check the fan for blocked outlet or

other damage.

Open the filter unit’s inlet inspection

door on the top of the inlet and

check for blockage, clean if

necessary.

If the inlet is blocked/partly blocked

by sticky dust/particles open the

inspection panel on the top of the

unit and clean the preseparator.

NO

YES

Is the fan operating correctly?

Does the impeller rotate in the

right direction?

Contact your nearest Nederman

representative for advice.

Check the rotating direction of

the fan impeller. Compare with

the arrow on the label on the fan

motor. It is very important that

the rotation direction is right.

If the impeller rotates in the wrong

direction, the fan gives only 40 %

of its possible air volume. Contact

a qualified electrician if the im-

peller rotation must be reversed.

Has the airflow been satisfactory?

NO

The airflow is insufficient.

E

Go to

D

YES

Is the pressure resistance high

( >1000-1500 Pa)?

Summary of Contents for FilterMax DX 3000

Page 36: ...36 INSTALLATION AND SERVICE PROTOCOL 4 Point no Date Note ...

Page 37: ......