18

OPERATING DESCRIPTION

It is recommended to use a downtime

damper which should be mounted close to

the inlet (see picture page 16). The damper

closes the duct when FilterMax DX is shut

off, which will prevent dust from being

transported back into the workshop by the

air pulses from the down time cleaning.

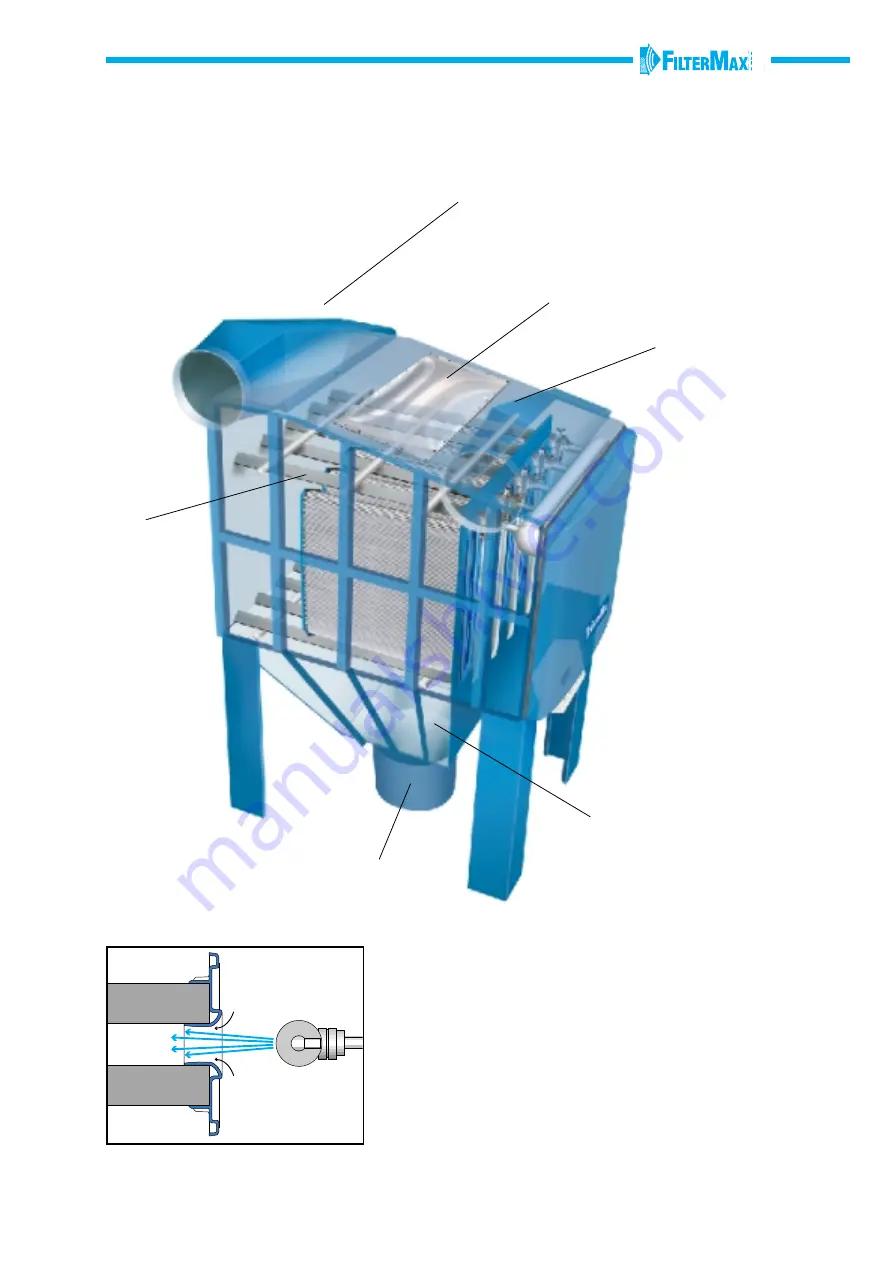

The contaminated air is led through the inlet which is

shaped to distribute the air evenly into the filter. Inside

the inlet there are four blades that further enhance the

air distribution. This design also minimises the

pressure loss in the inlet.

The filter cartridge seen from above

The filter cartridges are cleaned one

by one with powerful air pulses. The

air pulses are distributed into the slot

shaped outlet of the filter cartridges.

The distribution generates a quiet and

efficient cleaning pulse.

The filter controller controls the

cleaning process.

Valve with

cleaning pipe

Explsion relief panel, unloads the

pressure at an explosion.

The cleaned air exits

through the outlet in

the top of the front

part of FilterMax DX.

The air stream is led down-

wards by the sloped roof of

FilterMax DX towards the

filter cartridges. The filter

media in the cartridges

collects the remaining

particles.

Collection chamber

leading down to the

dust container.

Dust collector

Filter

protection

panels.

Summary of Contents for FilterMax DX Series

Page 36: ...36 INSTALLATION AND SERVICE PROTOCOL 4 Point no Date Note ...

Page 37: ......