FlexPAK 800/1000

19

EN

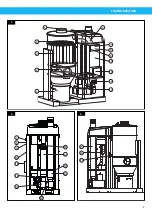

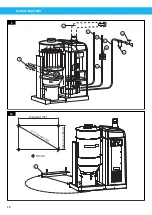

9.

Emergency switch, see figure 3 and 4.

10.

Frequency converter, see figure 3 and 4.

11.

Frequency converter cooling air filter, see figure 3 and 4.

12.

Cooling valve, see figure 3 and 4.

13.

High pressure side channel fan, with pump characteristic, see figure 3 and 4.

14.

PT100 sensor, see figure 4.

15.

Outlet silencer after fan, see figure 4 and 5.

16.

Cooling air hose from the frequency converter cabinet, see figure 5.

17.

Inlet silencer before fan, see figure 4.

18.

Pressure sensor, see figure 4.

19.

Acoustic enclosure, see figure 4.

20.

Compressed air supply, see figure 5.

3.6

Connections

NOTE!

The exhaust air duct is to be routed straight and as short a distance as possible.

NOTE!

The unit is CE-marked. Connections to the unit, initial start-up and maintenance are

to be carried out according to the product manuals.

Equipment such as cables and hoses are not supplied and are to be obtained locally.

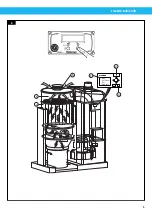

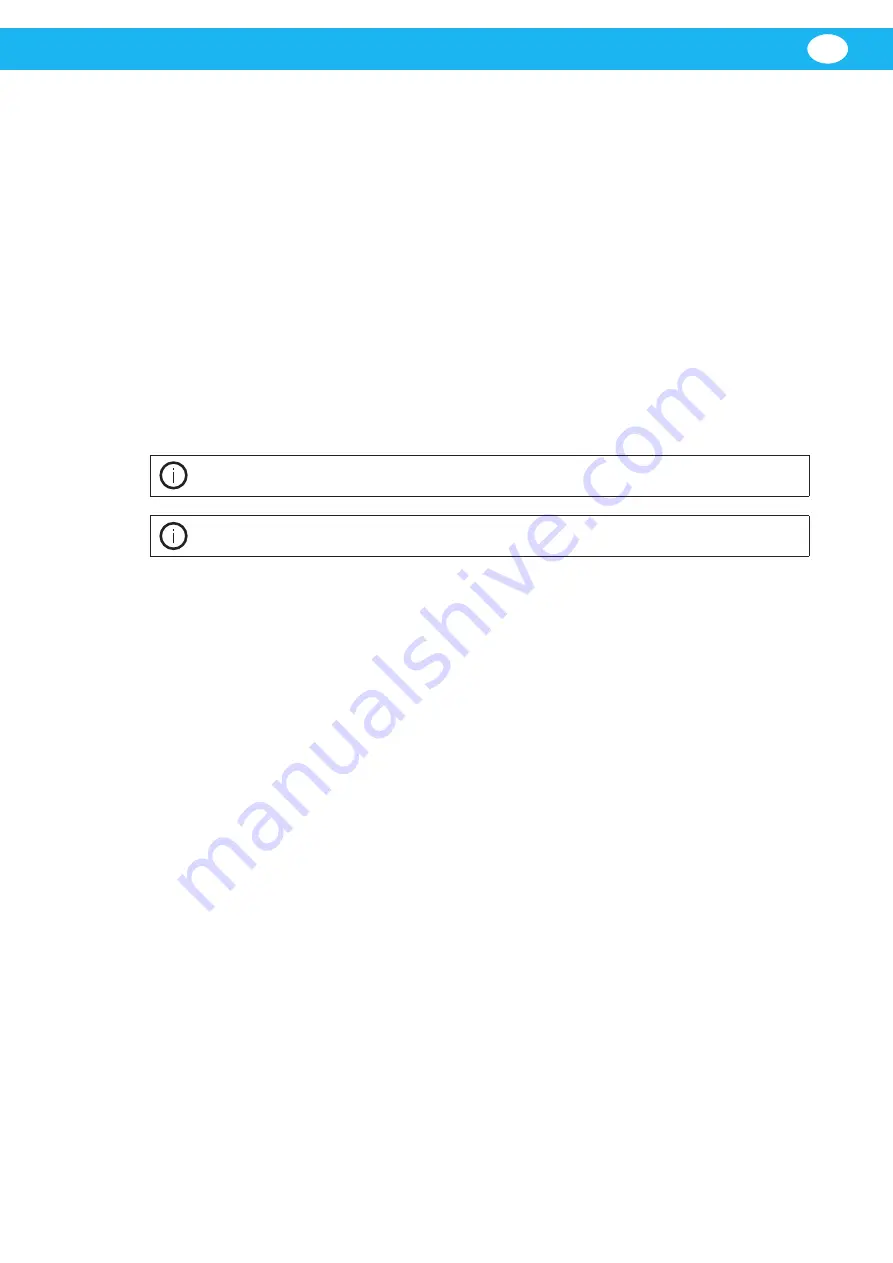

Figure

9

shows the normal connections to the unit. They are as follows:

1.

Inlet Ø 150 mm.

2.

Exhaust air duct, Ø 160 mm (for lengths <12 m).

3.

PS cable from valves at workstations.

4.

Incoming 3-phase power supply with a Protective Earth (PE) cable.

5.

Compressed air supply, Ø 6 mm nylon hose.

6.

Compressed air valve, size G1/4” or G1/2”.

7.

Water and dirt trap. Compressed air supply is to be clean and dry.

8.

Maintenance switch according to standard.

9.

Power cable to the unit.

3.7

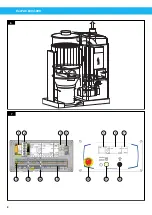

Start and control unit

The unit has a start and control unit, see figure

7

. The start and control unit has the

following components:

1.

Transformer TR1, 60 W.

2.

Connection block for the transformer TR1.

3.

Transformer primary fuses F2 and F3.

4.

Terminals for external emergency stop.

5.

Programmable Logic Controller (PLC).

6.

Data Unit 2 (DU2), I/O module.

7.

AM 2 PT100, temperature sensor input expansion module.

8.

Filter cleaning/test start button.

9.

Standby/Running button, which is the On/Off button.

10.

Emergency switch.

Summary of Contents for FlexPAK 1000

Page 8: ...FlexPAK 800 1000 8 1 2 3 4 5 6 7 14 13 12 11 9 8 10 7 6 ...

Page 10: ...FlexPAK 800 1000 10 9 10 1643 1mm 65 662 1mm 26 2 1771 4 1mm 70 Ø13mm 2 1 4 5 6 8 7 9 3 1 ...

Page 11: ...FlexPAK 800 1000 11 11 12 14 13 ...

Page 12: ...FlexPAK 800 1000 12 1 0m 39 4 A B C 16 17 15 Min 2 1m 83 A A A A C ...

Page 14: ...FlexPAK 800 1000 14 ...

Page 55: ...FlexPAK 800 1000 55 CS ...

Page 76: ...FlexPAK 800 1000 DA 76 ...

Page 97: ...FlexPAK 800 1000 97 DE ...

Page 98: ...FlexPAK 800 1000 DE 98 ...

Page 119: ...FlexPAK 800 1000 119 ES ...

Page 120: ...FlexPAK 800 1000 ES 120 ...

Page 141: ...FlexPAK 800 1000 141 FI ...

Page 142: ...FlexPAK 800 1000 FI 142 ...

Page 163: ...FlexPAK 800 1000 163 FR ...

Page 164: ...FlexPAK 800 1000 FR 164 ...

Page 205: ...FlexPAK 800 1000 205 IT ...

Page 206: ...FlexPAK 800 1000 IT 206 ...

Page 227: ...FlexPAK 800 1000 227 NL ...

Page 228: ...FlexPAK 800 1000 NL 228 ...

Page 270: ...FlexPAK 800 1000 PL 270 ...

Page 292: ...FlexPAK 800 1000 PT 292 ...

Page 314: ...FlexPAK 800 1000 RU 314 ...

Page 335: ...FlexPAK 800 1000 335 SV ...

Page 336: ...FlexPAK 800 1000 SV 336 ...

Page 356: ...FlexPAK 800 1000 ZH 356 ...

Page 357: ......

Page 358: ...www nederman com ...