L-PAK 150/250 Standard

13

EN

6.2

Parameter settings

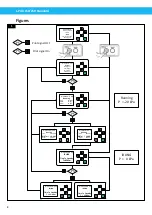

The following PLC displays show the different settings that can be configured for the unit.

6.2.1

Adjust the time and date

ESC

OK

Thu 10:45

2018-02-01

ESC

OK

NEDERMAN

Hi Vacum Unit

L-PAK Standard

OFF

TimeTo Service

2000 Hours

ESC

OK

Stop

>

Program

>

Setup

>

Network

>

Diagnos

ti

cs

>

ESC

OK

Msg Con

fi

g

>

Start Screen

>

Clock

>

LCD

>

Menu Language

>

Switch to OP

ESC

OK

Set Clock

>

S/W

ti

me

>

Sync

>

Thu

1

0:45

2018-02-01

ESC

OK

Set Clock

Do the following to adjust the time and date:

1.

From a PLC status screen, press the down arrow to go to the date and time screen.

2.

Press ‘Escape’

ESC

to get to the main menu.

3.

Press the down arrow to go to

‘Setup’

. Press ‘OK’

OK

to confirm.

4.

Press the down arrow to go to

‘Clock’

. Press ‘OK’

OK

to confirm.

5.

Press the down arrow to go to

‘Set Clock’

. Press ‘OK’

OK

to confirm.

6.

Use the left and right arrows

to move to cursor to parameter value. Press ‘OK’

OK

to confirm.

7.

Use the up or down arrows

to set Time or Date. Press ‘OK’

OK

to confirm.

Weekday is automatically set by the date.

8.

Press ‘Escape’

ESC

3 times to go to the time screen.

9.

Press the up arrow to exit.

NOTE!

There are several other input menus on the same level as the date and time screen.

If pressing the down arrow takes the PLC to one of those menus, use the left arrow to

get to the date and time screen.

6.2.2

H-Meter 1

Menu for setting the service interval. The default value is 2000 hours.

ESC

OK

H-Meter

1/1

MI

=2000h:0m

OT

=0h:15m

MN

=1999h:45

MN Ext =2000

MI = Configured, time, between, maintenance interval

OT = Accumulated, total operating time

MN = Time left until next maintenance

MI = 2000h: The amount of time between service intervals.

MI = 2000h: The amount of time between service intervals.

Summary of Contents for L-PAK Series

Page 2: ......

Page 3: ...L PAK 150 250 Standard 3 Figures 4 English 5...

Page 16: ......

Page 17: ...www nederman com...