L-PAK 150/250 Standard

EN

6

1

Preface

Read this manual carefully before installation, use and service of this product. Replace

the manual immediately if lost. Nederman reserves the right, without previous notice, to

modify and improve its products including documentation.

This product is designed to meet the requirements of relevant EC directives. To maintain

this status, all installation, maintenance and repair is to be done by qualified personnel

using only Nederman original spare parts and accessories. Contact the nearest authorized

distributor or Nederman for advice on technical service and obtaining spare parts. If there

are any damaged or missing parts when the product is delivered, notify the carrier and the

local Nederman representative immediately.

2

Safety

This document contains important information that is presented as either a warning,

caution or note. See the following examples:

WARNING!

Risk of personal injury.

Warnings indicate a potential hazard to the health and safety of personnel, and how that

hazard may be avoided.

CAUTION!

Risk of equipment damage.

Cautions indicate a potential hazard to the product but not to personnel, and how that

hazard may be avoided.

NOTE!

Notes contain other information that is important for personnel.

3

Description

WARNING!

Risk of personal injury.

See the User manual.

4

Unit operation

4.1

Software with extended functionality

L-PAK 150/250 Advanced comes with extended software and standard Logo! PLC display

that allows a technician to easily set parameters and read status messages.

NOTE!

If the software is used in a logo without a display, it is not possible to change

parameter settings.

Summary of Contents for L-PAK Series

Page 2: ......

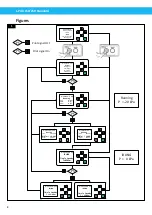

Page 3: ...L PAK 150 250 Standard 3 Figures 4 English 5...

Page 16: ......

Page 17: ...www nederman com...