NEX D/DX

1

7

5

Operation

WARNING!

Ignition risk for some dust or solvents.

•

Do not collect material that is caustic, explosive, highly flammable,

chemically

unstable, spontaneously ignitable, or which can release

sparks.

•

Check that no objects

that

can cause

a

spark or fire are sucked in

to the arm, or

impact against the hood.

•

Avoid mixing dust from different processes, for example service

S

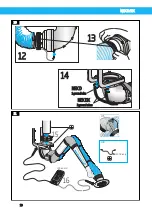

ee Figure 12. The extractor arm can easily be positioned at any point

within its

working area. It can be rotated 180

0

when wall mounted and 360

0

when ceiling

mounted. For best capture

,

the hood should be positioned as near the fume or dust

generating process as possible. The hood (on some models) is equipped with a

damper which can be adjusted with a lever.

Max

air flow:

1000 cfm (

1700 m

3

/h

r)

. Also check local directions.

Always check that the airflow is sufficient in the hood before work

begins.

Insufficent airflow depends on:

•

The fan impeller rotating in the wrong direction.

•

Hood, hose or 90

0

-bend are blocked.

•

Filter cartridges are blocked.

6

Service and

C

eaning

Treat NEX D/DX as a part of other machinery and clean it according to the cleaning

procedure plan.

C

lean and check it periodically according to the instructions

in sections 6.1 to 6.4.

WARNING!

Risk of personal injury.

•

Use a dust filter mask and other necessary

PPE

safety equipment when

cleaning

the

NEX D/DX.

•

There is a s

queeze/crush risk at

the

horizontal link on 4m and 5m

models

.

The NEX D/DX can be dry or wet cleaned:

•

Dry cleaning:

V

acuum

&

wipe the components externally and

internally if

necessary.

•

Wet cleaning: Use a detergent solution that will not damage

the product. S

ee section

3

for materials of construction

. Follow advice from the

manufacturer of the detergent

solution

regarding dosage and washing

method. Rinse with clean wate

r using

low

pressure and

hot

water

100-100

0

F

Av

oid directly rinsing sleeves, joints and so on. Let the NEX-arm dry

before it is used

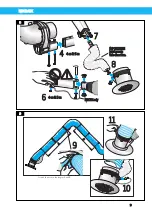

6.1

Internal cleaning of hood, hose and 90

0

-bend

1.

Detach hood and hose.

2.

Carry out dry or wet cleaning according to instructions in

section 6

above.

3.

Let the components dry.

4.

Re-fit the components. Stretch the hose along the lengths A and B.

5.

Connect the hose spiral to

ground

, see Figure 13. Make sure the NEX

D/DX is

properly

grounded

. See figure 11 and section 4.3

Grounding

.

Summary of Contents for NEX D Series

Page 2: ......

Page 8: ...NEXD DX 8 91 00 m 75 9 NEX NEX NEX ...

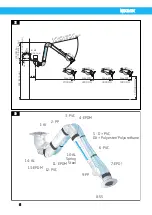

Page 11: ...11 3600 A A B 5 5 1 3 12 13 NEXD DX ...

Page 12: ...NEXD DX 12 A 13 mm 1 2 B 1 3 m m 1 2 C1 C2 C3 14 15 ...

Page 13: ...13 C5 C4 C7 C6 C8 16 NEXD DX ...