13

Prior to installation, always follow the

instructions and warnings in the chapter

entitled ”Safety instructions”!

Exhaust-air mode

The exhaust air is conveyed upwards via a

ventilation shaft or directly through the outer

wall to the exterior.

NOTE:

The exhaust air must not be conveyed

into a functioning smoke or exhaust gas flue or

into a shaft which is used to ventilate

installation rooms which contain heating

appliances.

Before conveying the exhaust air into a

non-functioning smoke or exhaust gas flue,

obtain the consent of the appropriate heating

engineer.

Discharge exhaust air in accordance with

the official and statutory regulations (e.g.

regional building laws).

If the exhaust air is conveyed through the

outer wall, a telescopic wall box should be

used.

To ensure optimum performance, the

extractor hood requires:

– a short, straight exhaust air pipe and

– the largest possible pipe diameter.

If pipe bends cannot be avoided, ensure

the largest possible radii.

NOTE:

If long, rough exhaust air pipes, a lot of

pipe bends or pipe diameters less than

150 mm are used, the air capacity will be less

than optimum and there will be an increase in

noise.

Use only pipes or hoses made of non-

combustible material for installation of the

exhaust air duct.

The manufacturer of the extractor hoods is

not responsible for complaints which can be

attributed to planning and design of the

pipework.

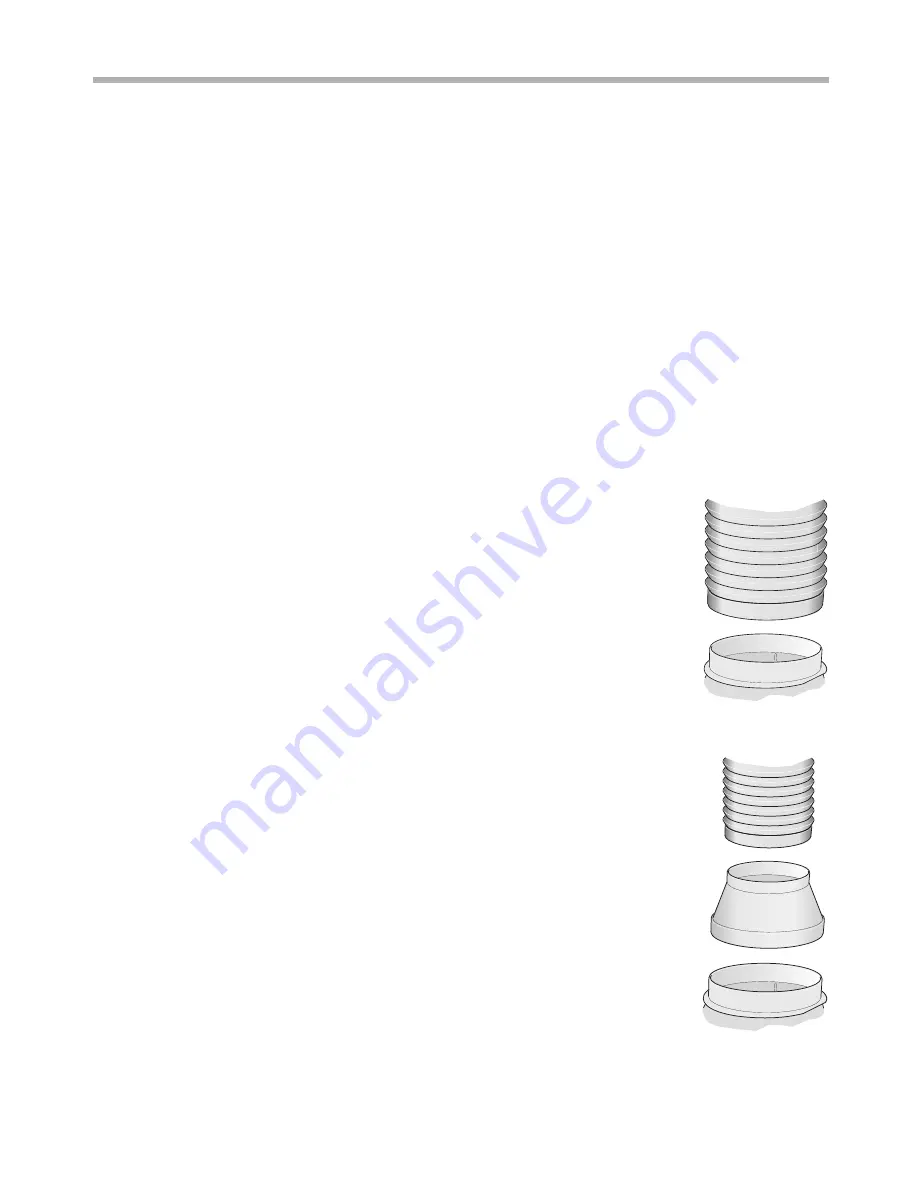

Connecting pipes

The diameter of the exhaust air pipes

should not be less than 150 mm.

Round pipes:

We recommend an inner diameter of

150 mm, however at least 120 mm.

Flat ducts

must have the same inner cross-

section as round pipes.

There should be no sharp bends.

Ø 150 mm approx. 177 cm

2

Ø 120 mm approx. 113 cm

2

If pipe diameters differ:

Use sealing strips.

Connection of 150 mm ø exhaust air pipe

(recommended size)

Attach exhaust air pipe

directly to the air-pipe

connector and seal

appropriately. If using an

aluminium pipe, smooth the

connection area beforehand.

Connection of 120 mm ø exhaust air pipe

Attach reducing

connector directly to the air-

pipe connector.

Attach exhaust air pipe to

the reducing connector.

Seal both joints

appropriately.

Installation instructions

Summary of Contents for D72F58N0GB

Page 1: ...Installation instructions and how to use and look after your built in cooker hoods NEFF UK Ltd...

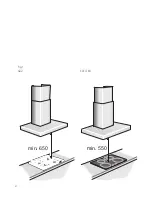

Page 2: ...Abb 1 ELECTRO Fig 1 GAZ min 650 min 550 2...

Page 18: ...18 Notes...

Page 19: ...19 Notes...

Page 20: ...20 Notes...

Page 21: ...21 Notes...

Page 22: ...22 Notes...

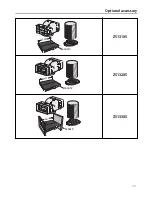

Page 23: ...23 Optional accessory Z5131X5 Z5132X5 Z5133X5 669419 236 669659 321 669648 281...