en

Installation

26

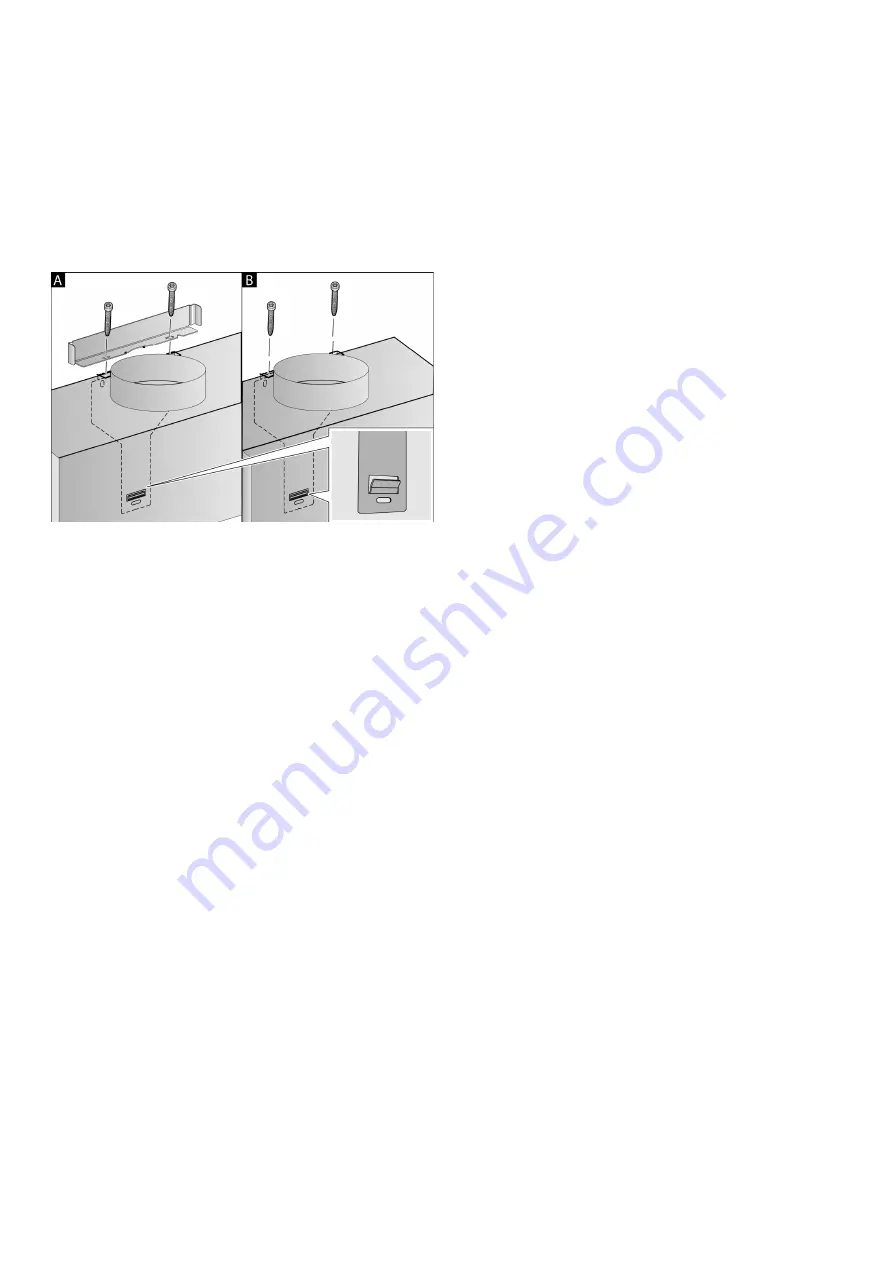

Wall-mounting the appliance and levelling it

1.

First remove the protective film from the back of the

appliance and, following installation, remove the rest

of the film.

2.

When mounting the appliance, ensure that it

engages properly with the mounting supports.

3.

If required, the appliance can be moved to the right

or to the left.

4.

Firmly tighten the screws for the mounting supports.

Hold the bracket firmly when doing so.

¨

5.

If no duct is to be fitted, screw in the two locking

screws without the bracket.

©

Connecting the pipes

If the extractor hood is to be operated in exhaust-air

mode, the pipes must be connected. If the extractor

hood is to be operated in air-recirculation mode, an

optional accessory must be fitted. To do this, refer to

the installation instructions provided.

Note:

If an aluminium pipe is being used, smooth the

connection area beforehand.

Exhaust air pipe, dia. 150 mm (recommended size)

Fit the exhaust air pipe directly to the air-pipe connector

and seal the joint.

Exhaust air pipe, dia. 120 mm

1.

Fit the reducing connector directly to the air-pipe

connector.

2.

Attach the exhaust air pipe to the reducing

connector.

3.

Use suitable means to seal both joints.

Attaching the flue duct

If the extractor hood is to be operated in exhaust-air

mode, a flue duct must be fitted.

The flue duct does not need to be fitted for air-

recirculation mode.

:

Warning

Risk of injury!

From sharp edges during installation. Always wear

protective gloves while installing the appliance.

:

Warning

Risk of electric shock!

Components inside the appliance may have sharp

edges. These may damage the connecting cable. Do

not kink or pinch the connecting cable during

installation.

1.

Separate the flue duct sections by removing the

adhesive tape.

2.

Remove the pieces of protective film from both flue

duct sections.

3.

Push one flue duct section into the other.

Notes

– To prevent scratches, lay paper over the edges of

the outer flue duct section to protect the surface.

– The slots of the inner flue duct section point

downwards.

4.

Place flue ducts sections on the appliance.

5.

Slide the inner flue duct section upwards, attach it to

the left and right sides of the retaining bracket, and

then slide it down to engage it.

¨